Blind and/or buried via, built-up laminations

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

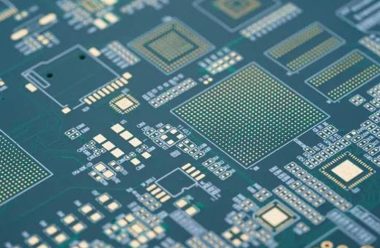

HDI blind and buried microvias,built-up laminations

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

HDI blind and buried microvias,built-up laminations

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

HDI blind and buried microvias, built-up laminations

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

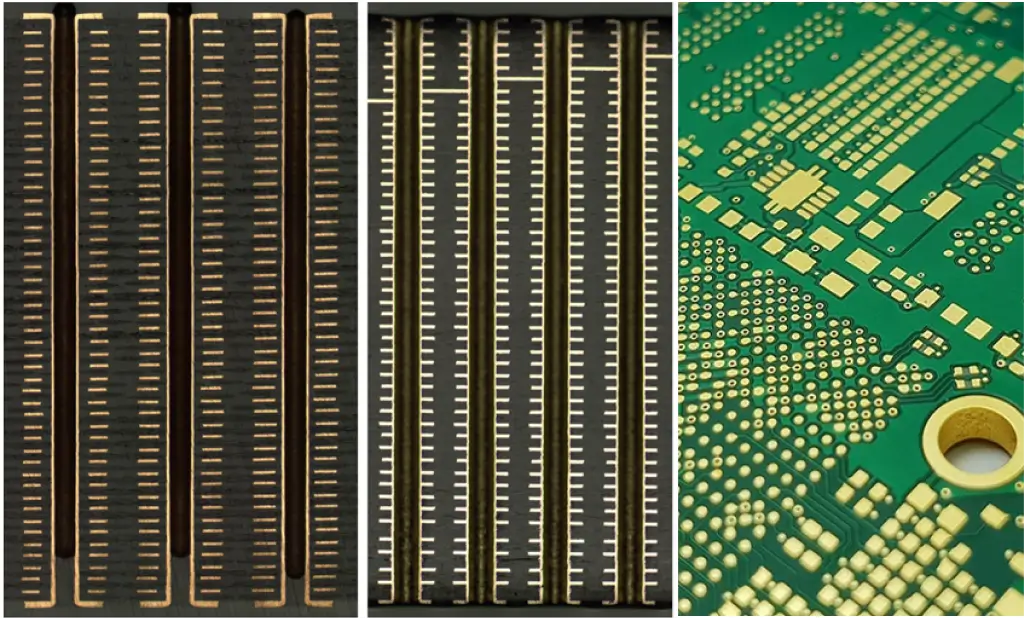

Blind and/or buried via, Fine line and fine pitch BGA

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

HDI Blind and Buried Microvias, Fine line and fine BGA pitch

High frequency low loss PCB material, low loss high speed PCB materials, Rigid-flex and flexible PCB manufacturer

High-Quality PCB Manufacturing & Assembly Services for Custom PCB Board Solutions

PCB Manufacturing

As a professional PCB board manufacturer with over 15 years of experience, we specialize in comprehensive PCB manufacturing and printed circuit board assembly services. Our capabilities cover custom PCB fabrication, flexible PCB (including flexible printed circuit board and rigid-flex PCB board), HDI PCB, high-frequency RF PCB, and standard pcb circuit board production. We provide one-stop pcb assembly solutions (SMT, through-hole, BGA/uBGA/QFN) that meet IPC Class 2/3 standards, serving automotive, medical, telecom, and industrial sectors. Our pcb fab facility is equipped with advanced pcb printing and fabrication equipment, ensuring high precision for print pcb board and printing circuit boards projects with fast turnaround times and competitive pricing.

Our PCB Manufacturing Capabilities

| PCB Product Type | Minimum Line Width/Space | Minimum Hole/Microvia Diameter | Layer Range | Core Material | Surface Finish Options | Application Scenarios |

|---|---|---|---|---|---|---|

| Standard PCB board | 3/3mil | 0.2mm (standard via) | 2-100L | FR-4 | HASL, ENIG, OSP, Immersion Tin | Consumer electronics, industrial controllers, smart home devices |

| HDI PCB | 2/2mil | 0.1mm (blind/buried microvia) | 4-100L | High-Tg FR-4, Rogers 4000 series | ENIG, Immersion Silver, ENEPIG | Medical devices, 5G telecom modules, portable wearables |

| Flexible PCB board | 2/2mil | 0.15mm | 1-30L | Polyimide (PI), LCP | ENIG, Coverlay, Solder Mask | Automotive ADAS sensors, wearable tech, aerospace wiring |

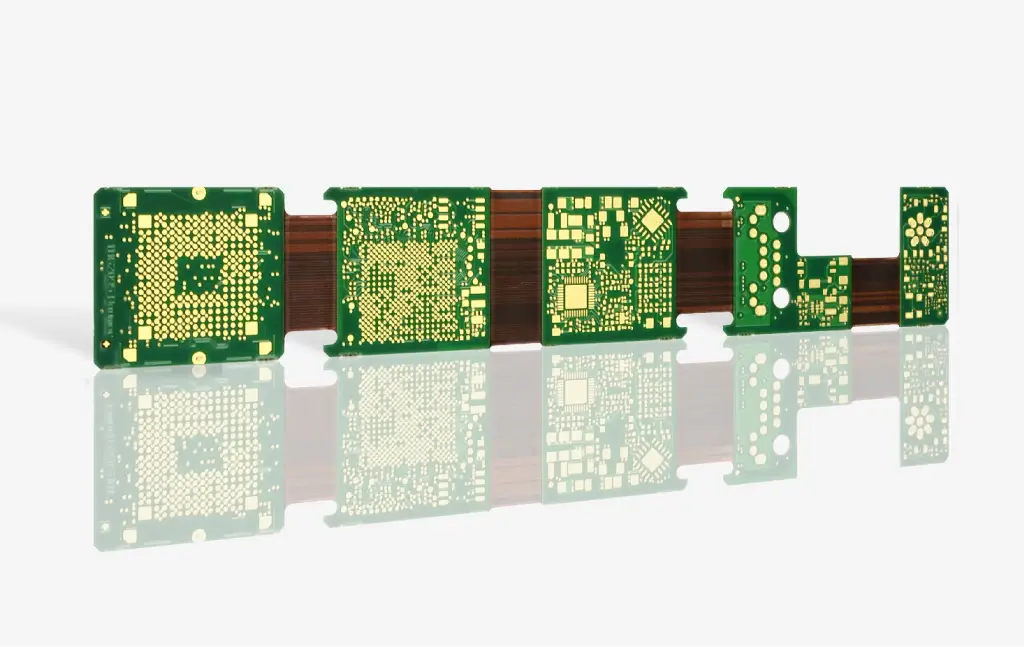

| Rigid-Flex PCB | 2/2mil | 0.15mm (flex zone) / 0.2mm (rigid zone) | 2-20L (rigid) + 1-6L (flex) | FR-4 + Polyimide | ENIG, Immersion Tin | 3D device assemblies, EV battery management systems (BMS), medical implants |

| HDI Rigid-Flex PCB | 2/2mil | 0.1mm (blind/buried microvia) | 4-100L | FR-4 + Polyimide | ENIG, Immersion Silver, ENEPIG | Medical devices, 5G telecom modules, portable wearables |

| Custom printed circuit board | 1/1mil (ultra-fine) | 0.08mm (custom microvia) | 1-40L | FR-4, Rogers, Biocompatible PI | Customized (per project demand) | Aerospace systems, medical diagnostic tools, high-frequency radar |

Standard PCB Board Fabrication

We deliver consistent, high-yield standard PCB fabrication for consumer electronics and industrial control systems. Our manufacturing process supports 2–100 layer architectures, 3/3mil line width/space specifications, and 0.15mm minimum hole diameters, with surface finish options spanning HASL, ENIG, and OSP. All standard printed circuit boards comply with IPC-A-600 standards, with flexible lead times optimized for both rapid prototype iterations and mass production deployments.HDI PCB with Microvia Technology

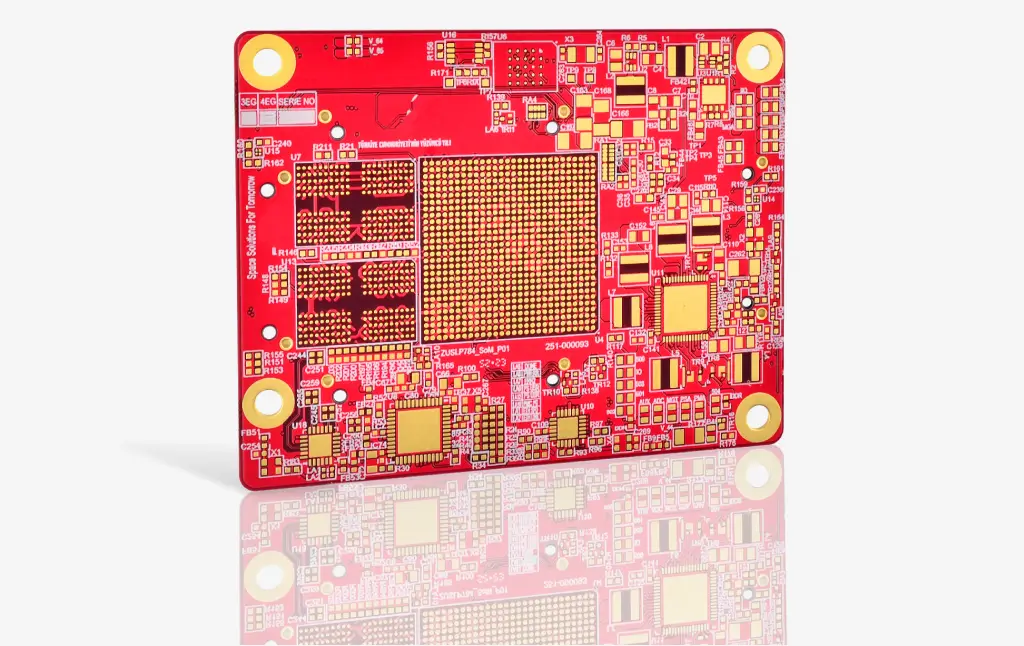

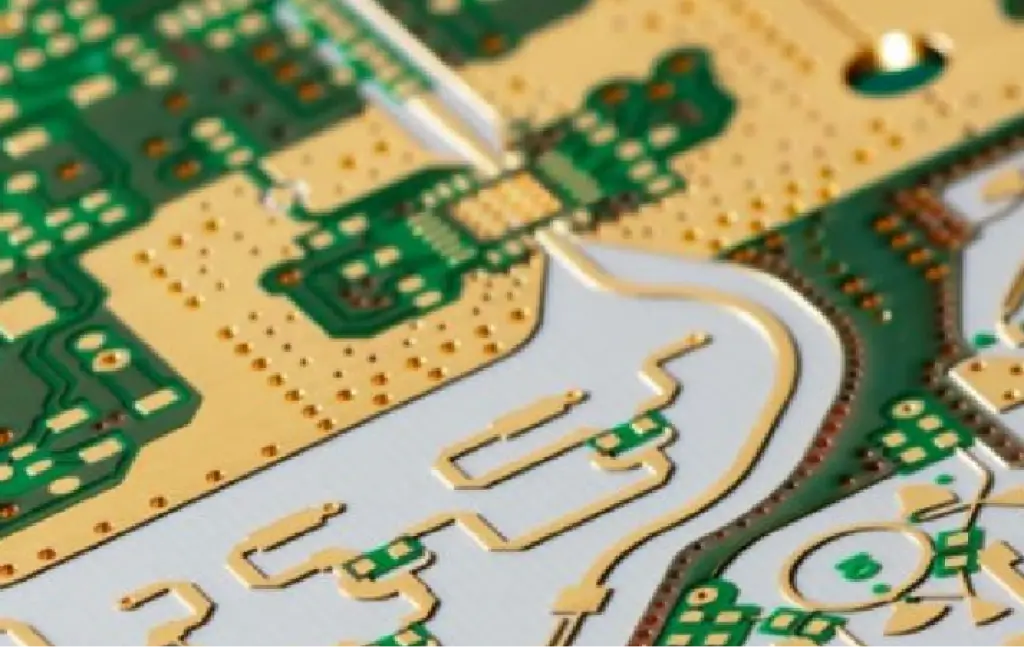

Our HDI PCB solutions leverage advanced blind and buried microvia technology, engineered specifically for compact medical devices and high-performance 5G telecom hardware. These circuit boards accommodate 4–32 layer designs, 2/2mil line width/space, and 0.1mm microvia diameters—enabling a 30% higher component density than conventional PCBs while preserving signal integrity for high-speed data transmission. We employ precision laser drilling to create microvias, ensuring compliance with the stringent quality benchmarks required for high-end electronic products.Flexible & Rigid-Flex PCB Solutions

We specialize in flexible and rigid-flex PCB manufacturing for automotive ADAS sensors, wearable electronics, and aerospace applications. Our flexible printed circuit boards achieve a bending radius as low as 0.5x the board thickness, paired with 2/2mil line width/space and 0.15mm minimum hole sizes. Protective coverlay layers can be integrated to enhance durability, while rigid-flex variants combine the flexibility of flex circuits with the structural stability of rigid PCBs, ideal for 3D device assemblies that demand both form and function.Custom Printed Circuit Board Services

Our custom PCB fabrication caters to unique, high-complexity requirements—from 1/1mil ultra-fine line structures for semiconductor test fixtures to 40-layer designs for aerospace avionics systems. We offer tailored solutions with customizable material selections (FR-4, Rogers high-frequency substrates, polyimide) and specialized processes such as ±3% impedance control and back drilling to eliminate signal stubs. Our in-house engineering team provides comprehensive Design for Manufacturability (DFM) consulting, transforming complex PCB designs into production-ready, high-reliability products.Professional PCB Assembly Services

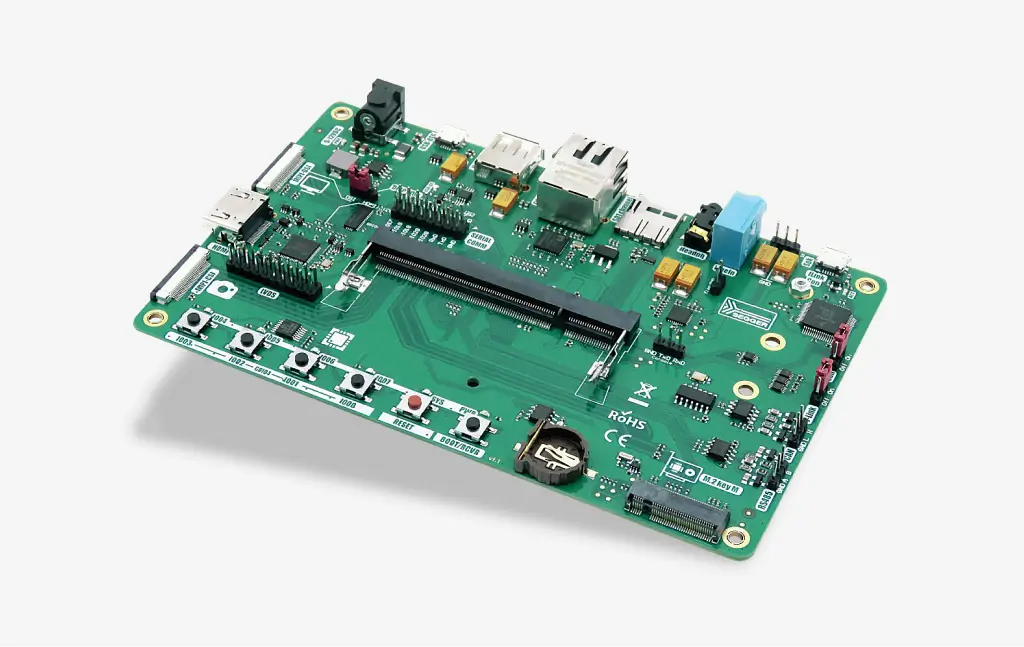

SMT & Through-Hole PCB Assembly

We provide end-to-end PCB assembly services, encompassing Surface Mount Technology (SMT) for 01005-sized passive components and through-hole insertion for large, heavy-duty connectors. Automated placement equipment ensures 99.9% component placement accuracy, while dedicated manual assembly stations handle delicate oversized parts that require precision handling. For mixed-technology projects, we seamlessly integrate SMT and through-hole processes to meet the assembly needs of consumer and industrial electronics alike.High-Precision BGA/QFN Assembly

Our high-precision assembly capabilities include soldering for Ball Grid Array (BGA), micro-BGA (0.2mm pitch), and Quad Flat No-leads (QFN) packages—critical for high-performance computing (HPC) and 5G infrastructure devices. We utilize 3D X-ray inspection to verify the integrity of hidden solder joints, paired with nitrogen-reflow ovens to minimize oxidation during the soldering process. This assembly service also supports Package-on-Package (PoP) and Chip Scale Package (CSP) configurations, catering to cutting-edge PCB designs that demand miniaturization and high reliability.IPC-Class Assembly Quality

All our printed circuit board assembly operations comply with IPC Class 2 (commercial-grade) and IPC Class 3 (high-reliability) standards. We implement 100% Automated Optical Inspection (AOI) to detect surface defects, coupled with functional testing for mission-critical products used in aerospace, medical, and automotive industries. Full traceability is maintained from component lot codes to final shipment, with compliance to FDA regulations, IATF 16949 (automotive), and AS9100 (aerospace) standards.Our PCB Manufacturing Advantages

Advanced PCB Production Equipment

Our manufacturing facility is equipped with state-of-the-art laser drilling systems (3μm positioning precision), Laser Direct Imaging (LDI) equipment for ultra-fine line patterning, and automated solder paste printers for PCB assembly preparation. The LDI system eliminates traditional film exposure errors, while laser drillers create 30μm microvias essential for HDI PCB production. We efficiently handle small-batch prototype orders (1–100 units) and large-volume manufacturing runs (100,000+ units), ensuring consistent quality across all order sizes.IPC & IATF Certified Production

As a certified PCB manufacturer, we hold IPC-A-600, IPC-610, IATF 16949 (automotive), and ISO 13485 (medical device) certifications. Our circuit board manufacturing process includes rigorous raw material testing and electrostatic discharge (ESD) protective packaging, ensuring full traceability for every product. These credentials make us a trusted partner for regulated industries where quality and compliance are paramount.Industry-Specific PCB Solutions

Automotive Flexible Circuit Board

Our flexible circuit boards for automotive ADAS, infotainment systems, and BMS meet AEC-Q200 standards, with an operating temperature range of -40°C to 125°C and 20G vibration resistance. These boards use flame-retardant polyimide substrates with integrated EMI shielding, while BMS-specific flexible PCBs feature 3mm×3mm copper coin reinforcements to handle high-current power paths.Medical Custom PCB Board

Our custom PCBs for medical devices utilize USP Class VI polyimide and adhere to IPC Class 3 quality standards, complying with FDA 21 CFR Part 820 and CE MDR regulations. Diagnostic tool PCBs support a standby current of ≤10mW for low-power operation, while implantable device PCBs incorporate hermetic sealing to prevent fluid contamination. All medical PCB assembly is performed in a Class 10,000 cleanroom environment to meet strict hygiene requirements.5G Telecom PCB Circuit

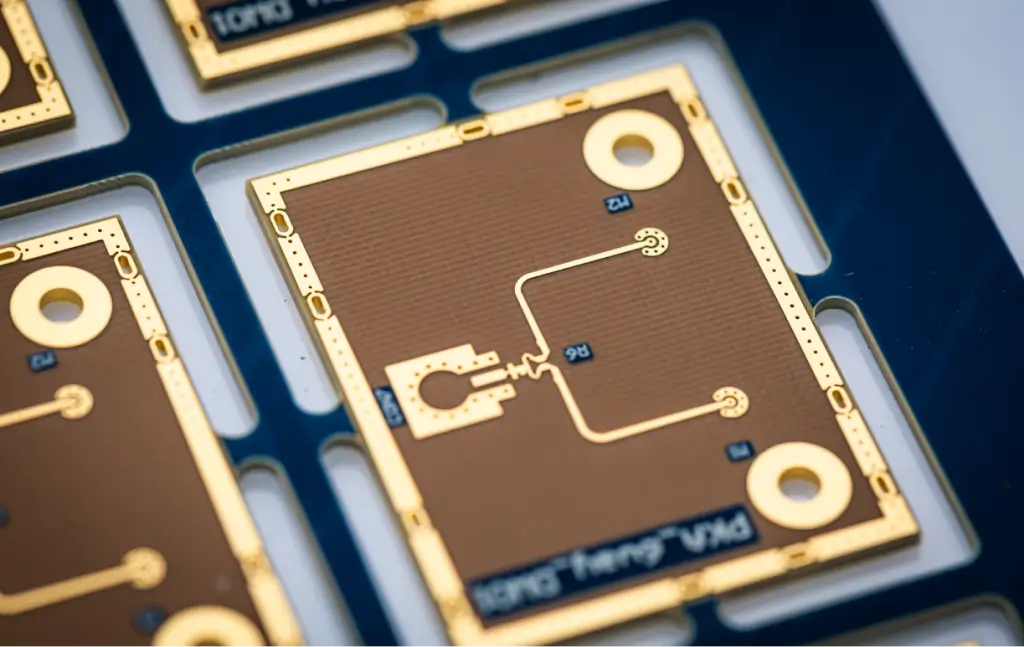

Our 5G base station PCBs use Rogers RO4350B and Taconic TLY-5 substrates—materials with low dielectric constant (Dk) and dissipation factor (Df)—to minimize signal loss in the 24–40GHz mmWave frequency band. These boards feature ±3% impedance control and back drilling to eliminate signal stub noise, with 6+N+6 HDI layer structures optimized for high-density 5G antenna arrays and transceiver modules.PCB FAQs & Technical Glossary

PCB Manufacturing vs. Assembly

PCB Manufacturing (PCB Fab/Fabrication) involves creating bare PCB boards through substrate cutting, copper etching, drilling, and surface finishing. PCB Assembly (Printed Circuit Assembly) is the subsequent process of soldering electronic components onto bare boards to produce functional circuit assemblies. Our one-stop service model eliminates supply chain bottlenecks and reduces overall lead times for our clients.Key PCB Technical Terms

- HDI PCB: High-Density Interconnect PCB featuring microvias and fine-pitch traces, designed for miniaturized devices such as smartphones, medical wearables, and 5G modems.

- ENIG Surface Finish: Electroless Nickel Immersion Gold—a corrosion-resistant coating applied to PCB surfaces to enhance solderability and long-term reliability, ideal for high-reliability applications like aerospace and medical devices.

- Blind/Buried Via: Specialized HDI PCB vias that connect partial board layers. Blind vias link outer layers to inner layers, while buried vias connect inner layers exclusively. Both reduce board size and improve signal integrity by eliminating unnecessary through-vias.

- IPC Class 3: The highest PCB quality standard defined by the IPC, reserved for critical applications such as aerospace, military, and life-saving medical devices. It mandates strict defect tolerance and rigorous performance testing.

HDI PCB

HDI PCBs are characterized by thin lines, closer spaces, and more dense wiring, which allow for a faster connection while reducing the size and bulk of a project. These boards also feature blind and buried vias, laser-drilled microvias, sequential lamination, and via in-pads.

We use the most advanced equipment and technology, including laser direct imaging, to hold tight tolerances so that we can meet today’s HDI PCB requirements.

HDI Circuit Board Features

- Layer count: 4~40L

- Board material: Ro4350B、Ro4003C、M6 series 、M7 series、EMC528(HF)、EMC891~K、EMC890~890K(HF)、Isola I-Tera、Isola TerraGreen、Tuc-933、Tuc-883

- Board thickness: 0.18mm min.

- Size: 18″ X 23″ (Shipping size)

- BGA Pitch: 0.35mm (min)

- Min trace width/spacing: 0.003″/0.003″

- Min thru hole size: 6mils (VIP resin filled) 8mils (VIP copper paste plugged)

- Min gap from PTH to track inner layers: > 6mils

- Thru hole aspect ratio(The board thickness vs. Drill hole size): 8~30

- Min/Max Laser drill hole size: 3mils / 8mils ( VIP plated shut)

- Aspect ratio (dielectric thickness/ Laser drill hole size): 0.8Max.

- HDI: 10+N+10(Anylayer)

- Back drill: Min hole size 15.7mils Depth tolerance +/-6mils

- Copper coin: length x width 3mm x 3mm(min) Surface flatness:30um(max)

- Layer to Layer Registration: +/-1.5mils min.

- Tolerance of impedance control: +/-5%

- Cavity Process: Laser cutting

- Board finishings: ENEPIG+Hard gold plating(Gold finger) Soft gold plating+Hard gold plating(Gold finger)

Ultra HDI PCB Features

- Lines/spaces: 25/35 μm

- Microvias/pads Ø: 50/150 μm

- Thinnest starting material: 75 μm

- Thinnest dielectric thickness: 50 μm

- Conductor width tolerance: +/- 10%

- Artwork to soldermask tolerance: +/- 15 μm

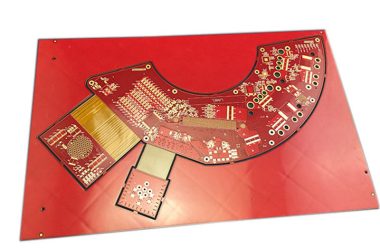

Flexible PCB

Flexible printed circuit boards (FPC) are offering the highest level of 3D miniaturization. Very low bending radii in combination with ultra-HDI (ultra-high density interconnect) are enabling our customers to build increasingly smaller and highly integrated devices. This technology is an enabler of small wearable devices as well it provides high signal density.

Benchuang Electronics has been a market leader in this field for many years and is manufacturing flex circuits with a layer-count of 1 to 16. We are working with polyimide foils as thin as 12.5 µm (0.5 mil) and adhesive bond plys starting at a thickness of 12.5 µm (0.5 mil). Our state of the art equipment is enabling us to produce FPCs with high output, reliability and repeatability. Depending on the dielectric thickness, laser drilled blind vias can be as small as 30 µm (1.4 mil) in diameter, and can be filled with copper in the subsequent plating process. This plating technology is enabling the use of stacked vias and via-in-pad structures.

Technological Highlights

- Turnkey flex solutions targeting 3D miniaturization

- Highly reliable, extremely robust multilayer flex/microvia substrates

- Ultra-thin base materials

- Filled via and stacked via process available

- Complex mechanical/assembly assist features, including special profiles, fold lines, cut-outs and thinned bending zones/cavities

- Wrap-around boards

- Chip-on-flex (COF), chip scale packaging (CSP) substrates, and BGAs

- A wide variety of surface finishes, for example; OSP, ENIG, ENEPIG, E-AU, DIG

- Flying leads

- Bending test for flexible circuits

- Ultra-fine line flex cables

Rigid Flex PCB

A technology that combines the best of two worlds – the stability of rigid boards and the flexibility of flexible circuits, pun intended!

Rigid flex circuit boards offer the best in packaging technology by merging the flexibility of flex circuits with the dense packaging of traditional rigid circuit boards. Combining the component and routing density of hardboards with the flexibility of flexible circuits, rigid flex PCBs allow designers to achieve routing density and interconnectivity that is not available in other types of circuit boards.

Benchuang Electronics is offering a big variety of rigid-flex PCB constructions, using high end/quality base materials, like high TG/low CTE FR4, combined with polyimide foils and various adhesives. State of the art interconnection technologies like stacked or staggered vias and via-in-pad structures are used to drive miniaturization further down the road. A big portfolio of surface finishings is enabling Benchuang Electronics' customers to use all available assembly methods on boards produced by us.

Rigid Flex PCB Features

- Available in layer counts above 20 layers for very high routing density

- Flexible layers typically 1, 2, 3 or 4, though more can be accommodated

- Controlled impedance in both rigid & flexible sections

- Very high reliability

- Minimum dielectrics: down to 1 mil in flex sections, 2 mil in rigid sections

- Largest library of rigid flex constructions approved to UL 94 V-0

- RoHS compliant

RF PCB

Benchuang Electronics has been providing trusted PCB manufacturing and fabrication services since 2007. We pride ourselves on having the deep engineering experience and advanced technology and equipment to handle any project all the way from layout through assembly in our state-of-the-art facility. This includes fabrication and manufacturing of radio frequency (RF) and microwave PCBs.

RF PCB Capabilities

- Layer count: 2~20L

- Board material: RO4350 B、Isola Astra MT77、RF35、RO4003 C、Ro3003、Ro3010、RT5870、RT5880、RT6010、Ro4360、TMM10、TMM10i、TACONIC RF series、TACONIC TLY series

- Double-sided process: RT5870、RT5880、RT6010、Ro4360、TMM10、TMM10i

- Hybrid: Ro3003、Ro3010、Ro4360、TACONIC RF series、TACONIC TLY series+ FR4

- Board thickness: 0.18mm(min)

- Size: 0.5″ X 0.5″ (min)(Shipping size)

- Min trace width/spacing: 0.005″/0.005″

- Tolerance of trace width / spacing: +/-8% trace width > 10mils and tolerance: +/-1mils

- Radius of Antenna width: 0.5mils(max)

- Min gap from Antenna to conductors: 3mils(min)

- Min thru hole size: 6mils (VIP resin filled) 8mils (VIP copper paste plugged)

- Min gap from hole edge to hole edge (Stitching via): 8mils

- Min gap from hole edge to copper (Stitching via): 6mils

- Aspect ratio: dielectric thickness / Laser drill hole size: 5mils / 6.50 mils(max) ( VIP plated shut )

- HDI: 6+N+6

- Layer to Layer Registration: +/-1.50 mils

- Tolerance of impedance control: +/-5%

- Cavity Process: Lamination (Adhesive Low Dk Low Df)+depth control milling

- Conductive via fill, Non-conductive via fill, Plated edges, Plated radii (castellation), Plated milling cutouts, Hard gold body, Soft bondable gold, Immersion gold, Immersion silver, HAL standard, HAL lead-free (ROHS), ENTEK (OSP)

High Frequency PCB

When it comes to high frequency PCB design, it’s important that the design engineer collaborate with the PCB supplier to select the materials for the desired frequency performance requirements and to establish the correct stack-up. Benchuang has deep engineering capabilities and experience with control depth drilling, control depth milling, and back drilling, unlike some of our competitors. This means we have the technology, the experience, and the knowledge to help you design and build the right high frequency PCB from the start.

We differentiate ourselves by being able to take on all complex jobs — all the way from layout through assembly — and we do this under one roof with state-of-the-art technology and an extensive engineering team. This end-to-end expertise allows us to excel at the entire process and be the best PCB provider in the word.

High Frequency PCB Capabilities

- Hybrid or Mixed Dielectric Boards (PTFE/FR-4 combinations)

- Board material: I-Speed、I-Tera® MT40、Tachyon-100G、Isola Astra MT77、Megtron 6 R-5775、Megtron 7 R-5785、Megtron 7N R-5785N、RO4350 B、RO4835、RO4003、RO4533、IT-968、IT-968 SE、IT-988G、IT-988G SE、EM-528K、EM-890K、TU-883、TU-883SP

- Cavity Boards (Mechanical and Laser Drilled)

- Edge Plating

- Constellations

- Large Format PCBs

- Front to back registration of etched cores to +/-0.05 mm

- +/- 0.0.025 mm tolerance on etched features for un-plated 1oz copper

- Blind/Buried, Via-in-Pad, Micro Vias, Stacked Vias, and Laser Via’s

- Soft Gold and ENEPIG Plating

- Sequential lamination

Printed circuit assembly

Benchuang Electronics is a reliable full turnkey PCB service solution for prototype quantities as well as small-volume to large-volume production runs, and a one stop PCB manufacturing and assembly company. As a provider of turnkey PCB services, our company offers professional consulting in Design for Manufacturing (DFM). Benchuang Electronics provides its customers with access to full turn-key, partial, and consigned assembly services, which means you have the option to buy the parts yourself (consigned) or allow us to take care of that for you (turn-key).Our integrated fabrication and assembly services ensure a smooth transition since everything is completed within the same building. By shortening the supply chain, you eliminate outside factors that can lead to delays and errors.

PCB Assembly capabilities

- SMT, Through Hole and Mixed Assembly

- Passive Down to 01005 Sizes

- Ball Grid Array (BGA)

- Ultra-Fine Ball Grid Array (uBGA)

- Quad Flat Pack No-Lead (QFN)

- Quad Flat Package (QFP)

- Plastic Leaded Chip Carrier (PLCC)

- SOIC, Package-On-Package (PoP)

- Small Chip Packages (Pitch of 0.2 mm)

- BGA, micro-BGA, QFN, CSP and any leadless devices up to .20mm pitch assembly with 100% 3D X-ray inspection

Get Touch For PCB Fabrication and Assembly

We’re here for you, and we look forward to serving you.