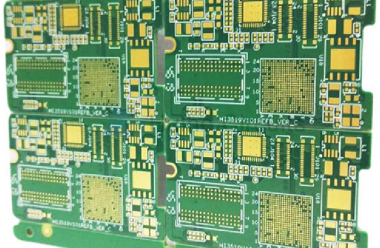

Designing printed circuit boards for 24 GHz and 77 GHz radar systems presents unique challenges in PCB manufacturing, particularly when leveraging HDI PCB manufacturing for high performance.

At these frequencies, signal wavelengths shrink to millimeter scales, requiring meticulous layer control, low-loss materials, and precise trace geometry Designing printed circuit boards (PCBs) for 24 GHz and 77 GHz radar systems is challenging, especially when using High-Density Interconnect (HDI) manufacturing.

At these extremely high frequencies, the signal wavelengths are incredibly short, so you need to be very precise with layer control, use low-loss materials, and create exact trace geometries to ensure high performance.

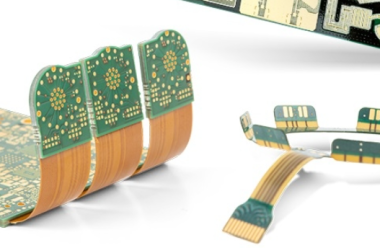

HDI circuit boards help meet these requirements by enabling tight trace spacing, microvias, and controlled impedance routing. For automotive or gesture-sensing radars, 24 GHz designs demand careful management of board footprints and interference.

Meanwhile, 77 GHz radar—commonly used in advanced driver-assistance systems (ADAS)—requires extremely low-loss dielectric and very high fabrication precision to support very high-speed signals. For both frequency bands, using High-Density Interconnect (HDI) printed circuit boards with multilayer stacks is a good idea because it improves signal integrity, mechanical reliability, and thermal stability.

By using layer stackups that have a consistent dielectric thickness, materials with a matched Coefficient of Thermal Expansion (CTE), and high-frequency laminates, you can make sure the boards work reliably even when temperatures and environmental conditions change.

RF Design and Signal Integrity

Radar PCBs at 24 GHz and 77 GHz require careful control of signal integrity. At these frequencies, losses due to skin effect, dielectric loss, and radiation become pronounced. Designers need to maintain tightly controlled impedance for microstrip or stripline traces, and minimize stubs, discontinuities, and via transitions.

The high density of microvias in HDI PCB manufacturing enables compact routing while keeping return paths close by, which lowers inductance and maintains signal fidelity. Trace width and spacing must be calculated using high-frequency models that account for the frequency-dependent dielectric constant (Dk) and loss tangent (Df) of board materials.

High-Density Interconnect (HDI) layouts minimize insertion loss and echo by establishing shorter connections between active components. Full-wave tools are essential for simulating radar modules’ electromagnetic behavior during design. In the end, this procedure guarantees consistent radar performance and dependable detection by anticipating and averting possible problems like board-level resonances, reflections, and layer coupling.

PCB Materials for High-Frequency Radar Applications

Selecting the right materials is critical for 24 GHz and 77 GHz radar PCBs. Standard FR-4 laminates exhibit high dielectric losses at these frequencies, so high-performance materials—like PTFE-based laminates or ceramic-filled substrates—are preferred. These offer stable dielectric behavior, low loss tangent, and consistent Dk across temperature.

HDI PCB manufacturing methods employing such materials reduce signal attenuation and phase distortion. Designers also need to consider thermal-cycle stability, since radar modules can go through wide temperature swings. Using materials with a low Coefficient of Thermal Expansion (CTE) that matches that of copper helps keep the layers aligned and prevents the board from warping.

Antenna Integration

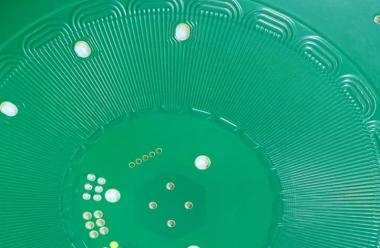

Radar systems often incorporate antennas directly onto the PCB. For both 24 GHz and 77 GHz designs, antenna layout must account for wave propagation, ground proximity, and coupling to feedlines. Printed patch antennas, Vivaldi elements, or slot antennas are common and must be precisely dimensioned to operate at target frequencies.

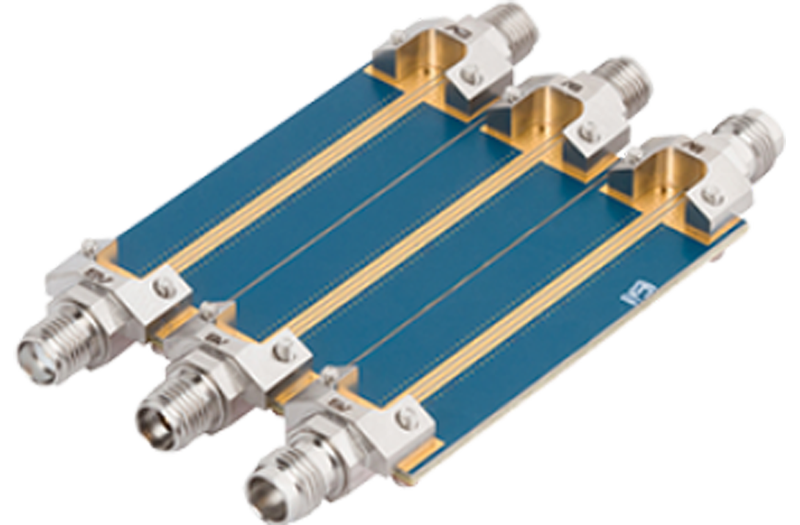

HDI PCB manufacturing enables antenna patterns with narrow features and consistent material properties. Reducing ground plane stubs and properly matching feedlines with microstrip or Substrate-Integrated Waveguide (SIW) designs are key factors in efficiency. Complex antenna feeding networks, like phased arrays or Butler matrices, can be built on a small board using layered interconnects. In order to maintain consistent beam patterns in spite of temperature and vibration variations, matched laminate stacks and balanced copper zones are crucial because thermal expansion and board warpage can detune antennas at millimeter-wave frequencies.

Efficiency depends on minimizing ground plane stubs and appropriately matching feedlines with microstrip or Substrate-Integrated Waveguide (SIW) designs. On a small board, layered interconnects enable the construction of complex antenna feeding networks, like phased arrays or Butler matrices.

In order to maintain consistent beam patterns in spite of temperature and vibration variations, matched laminate stacks and balanced copper zones are crucial because thermal expansion and board warpage can detune antennas at millimeter-wave frequencies.

Power Distribution and Noise Management

Radar modules require clean power supplies for low noise and phase coherence. Power planes in HDI circuit boards must have low impedance, robust decoupling capacitors, and minimal via-induced voltage drops. At mm-wave frequencies, power noise can bleed into sensitive front-end circuits, so power distribution paths must isolate RF sections.

Using buried capacitance or dedicated RF ground zones within the HDI stackup helps reduce noise coupling. Designers must simulate the behavior of the Power Distribution Network (PDN) to account for simultaneous switching currents and voltage drop under dynamic loads. This is essential for ensuring a stable bias for amplifiers and mixer stages.

Thermal Management

Because radar PCBs frequently include power amplifiers and other components that generate substantial heat, effective heat dissipation is crucial for maintaining performance and extending component lifespan.

HDI PCB manufacturing supports embedded thermal vias, high-copper density layers, and board-level heat spreaders to transport heat away from active components.

Materials with improved thermal conductivity, such as metal-core or thermally enhanced laminates, help conduct heat to external heatsinks or chassis. For 77 GHz applications in automotive radar, ambient temperature ranges can be wide; ensuring thermal stability prevents drift in local oscillators and preserves radar accuracy. Designers may include temperature sensors and compensating network paths to correct for frequency shifts due to thermal expansion. Proper thermal modeling during layout planning helps avoid hotspots and keeps power amplifiers operating within safe temperature limits.

Electromagnetic Interference (EMI) and EMC Compliance

At millimeter-wave frequencies, EMI and EMC requirements are stricter because of tighter modulation and sensitivity. To meet these standards, it’s essential to use proper shielding, maintain ground-plane continuity, and isolate digital and RF sections. HDI PCB manufacturing makes it possible to create partitioned ground planes and embed metal cans over sensitive areas.

Designers should use via fences around RF blocks, minimize slot radiation, and include proper filtering for connectors and cable interfaces. Automotive radar certification requires extensive conducted and radiated emissions testing, so effective layout-level EMI mitigation strategies are essential.

Reliability and Testing

Radar PCBs must be reliable because they must be durable enough for use in industrial, automotive, and aerospace settings. This is made possible by HDI manufacturing, which produces precise layer bonding and robust microvia structures that give the boards exceptional shock and vibration resistance. To ensure reliability, radar modules are put through rigorous tests like thermal cycling, humidity testing, and vibration stress. Because of their high frequency, radar waveforms can reveal even minor board defects like delamination or via impedance anomalies.

Designers should include test features such as RF test coupons, TDR access points, and built-in calibration loops. HDI printed circuit boards benefit from tighter tolerances and controlled impedance throughout the build, which reduces variation between units and eases qualification for reliability standards like AEC-Q100 or ISO 16750.

Integration with Radar Circuits

Radar front-end circuits—like low-noise amplifiers (LNAs), power amplifiers, mixers—must be placed close to antennas to reduce feedline loss. These RF modules can be integrated compactly thanks to HDI PCB layouts. Using split ground islands, microvias, and back-drilled via stubs guarantees symmetric current distribution, which is essential for proper grounding and return paths. Usually, designers use field-probing models to match trace impedance and minimize the trace length from the antenna to the Low-Noise Amplifier (LNA). By ensuring uniform layer registration and microvia geometry, HDI manufacturing lowers board-to-board performance variance.

Radar System Architecture and PCB Layout

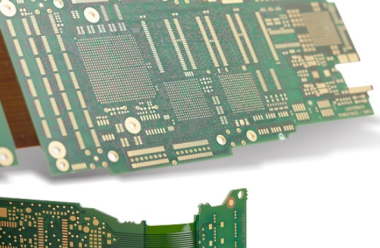

Radar systems are designed around frequency generation, signal processing, and antenna arrays. An RF section, an Intermediate Frequency (IF) block, baseband processing, and power management are all common components of a millimeter-wave radar board.

The RF, analog, and digital domains must be kept apart in the PCB layout. To preserve isolation and minimize cross-talk, HDI PCB manufacturing techniques are employed. Separate supply planes and shielding are necessary for high-speed digital sections. Routing should respect phase matching in antenna arrays.

HDI circuit boards allow optimized interconnect paths with staggered microvias and controlled-laminate stackups. In order to minimize connector losses, designers must arrange board layers so that RF signals are on top, followed by power and control layers. Early layout attention keeps high-frequency paths clean and reduces trace length between subsystems.

Future Trends and Emerging Technologies

Radar PCBs are moving toward multi-channel beamforming and digital beam steering. This places demands on HDI PCB manufacturing for finer microvia pitch, embedded waveguides, and integrated silicon interposers. Materials with ultra-low loss are being developed to support 120 GHz and beyond.

Additive manufacturing may enable 3D antenna structures printed directly onto boards. These trends require a tighter integration of materials, stack-up design, and RF simulation tools. HDI PCB production will need to support thinner features, consistent layer alignment, and precise impedance control for advanced radar modules.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)