What Is a Flexible Printed Circuit?

A flexible printed circuit—technically referenced as flexible pcb, flexible circuit board, flexible printed circuit board, or flexible pcb board—is a precision-engineered electronic interconnection platform constructed on pliable insulating substrates, predominantly polyimide (PI). This design enables repeated bending, folding, or twisting while preserving uncompromised electrical integrity, distinguishing it from rigid printed circuit boards. As a cornerstone of modern miniaturized electronics, the bendable circuit board is purpose-built to integrate into constrained spaces, dynamic systems, and irregular form factors.

Engineered to merge conductive copper traces, dielectric layers, and protective films into a lightweight, low-profile architecture, flexible pcbs are manufactured by specialized flexible circuit manufacturer and flexible printed circuit manufacturers in adherence to stringent industry standards. Key specifications include IPC-2223 (flexible circuit design) and IPC-6013 (performance and reliability criteria), ensuring consistent functionality across critical applications. The synergy of High Density, mechanical Flexibility, and Miniaturization—augmented by advanced features such as via-in-pad and controlled impedance—positions the flexible printed circuit as an indispensable component in consumer electronics, aerospace systems, medical devices, and automotive electronics.

Flexibility—Mechanical Foundation of Bendable Circuit Boards

Flexibility represents the defining mechanical attribute of a flexible printed circuit, enabling conformity to complex geometries, resistance to cyclic bending, and integration into dynamic assemblies where rigid PCBs are impractical. This characteristic is engineered through meticulous material selection and structural optimization, delivering quantifiable performance metrics for industrial and commercial applications.

- Material Engineering: Polyimide (PI) substrates—utilized in over 90% of precision flexible pcbs—exhibit an operational temperature range of -40°C to 125°C (extending to 300°C for high-temperature variants) and an elongation modulus of 15–30%, supporting 100,000+ cyclic bending cycles per IPC-2223 compliance testing. Polyester (PET) serves as a cost-effective alternative for low-stress applications, with a maximum elongation of 10% and operational temperature ceiling of 85°C.

- Bending Performance Metrics: Static bending radius as low as 3x the board’s total thickness (e.g., 0.3mm radius for a 0.1mm-thick flexible pcb board) and dynamic bending radius of 10x thickness for repetitive motion scenarios, such as foldable device hinges or robotic articulation points.

- Engineering Impact: Eliminates the need for bulky wiring harnesses, reducing assembly complexity and enabling integration with moving components—including robotic arms, wearable device straps, and automotive door modules. A qualified flexible printed circuit manufacturer can tailor flexibility parameters to specific application requirements, ranging from gentle contouring to full 180° folding cycles.

High Density & High Density Interconnect (HDI)

High Density and high density interconnect (HDI) are foundational to the flexible printed circuit’s capability to support complex electronic architectures within compact footprints. High density interconnect denotes the integration of fine-pitch traces, micro-scale pads, and advanced via technologies to maximize component density without compromising mechanical flexibility or signal integrity.

- Technical Specifications:

- Trace width/spacing: Minimum 25μm/25μm (0.001in/0.001in) for HDI-enabled flexible pcbs, compared to standard flexible circuit boards with 100μm/100μm pitch.

- Component density: Up to 200 active/passive components per cm², representing a 3x improvement over traditional flexible circuit boards.

- Layer configuration: Multilayer flexible pcbs (up to 16 layers) incorporating high density interconnect architecture, facilitating complex signal routing in space-constrained designs.

- Manufacturing Precision: Flexible printed circuit manufacturers employ laser ablation and photolithographic processes to achieve trace tolerance of ±5μm, ensuring consistent electrical performance across high-density layouts. Compliance with IPC-2226 (HDI circuit design standards) guarantees reliability for mission-critical applications, including aerospace and medical devices.

Miniaturization—Enabling Compact Electronic Systems

Miniaturization is a core technical advantage of the flexible printed circuit, driven by its ultra-thin profile, high density interconnect capabilities, and elimination of redundant interconnection components. This feature directly addresses the industry-wide demand for smaller, lighter electronic devices without sacrificing functional complexity or performance.

- Dimensional Advantages:

- Thickness: Single-layer flexible pcb board profiles as low as 0.08mm; 4-layer multilayer variants with a total thickness of 0.2mm.

- Weight-to-performance ratio: 70% lighter than rigid FR-4 PCBs of equivalent functionality (0.2–0.5g/cm² vs. 1.0–1.5g/cm² for rigid alternatives).

- Volumetric efficiency: Reduces device enclosure volume by 40–60% compared to rigid PCB assemblies, critical for wearables, implantable medical devices, and 5G transceivers.

- Application Impact: Enables the development of ultra-compact products such as true wireless earbuds (utilizing single-layer flexible pcbs) and implantable pacemakers (relying on miniaturized multilayer flexible printed circuits), where dimensional constraints are mission-critical.

Via Technologies—via-in-pad & Stacked/Staggered Vias

Advanced via technologies—specifically via-in-pad and stacked/staggered vias—are integral to realizing the flexible printed circuit’s High Density and Miniaturization objectives. These technologies optimize spatial efficiency, enhance signal integrity, and facilitate complex interlayer connectivity in high density interconnect designs.

via-in-pad

via-in-pad is a high density interconnect technique wherein vias are strategically placed directly within component pads, eliminating the need for dedicated via sites and maximizing available surface area for component placement.

- Technical Parameters:

- Via dimensions: Microvias with diameter ≤100μm for via-in-pad implementations, compared to 200μm+ for standard through-hole vias.

- Plating specifications: Conductive plating (copper-nickel-gold) to ensure electrical continuity and solderability, with minimum copper plating thickness of 20μm per IPC-6013.

- Performance Benefits: Increases component density by 25%, reduces trace length by 30% (minimizing signal propagation delay), and eliminates “dead zones” adjacent to traditional via placements.

- Target Applications: Critical for miniaturized devices including smartphone camera modules, IoT edge sensors, and implantable medical electronics, where space optimization is paramount. Flexible printed circuit manufacturers universally recommend via-in-pad for high-density designs requiring sub-1mm component spacing.

Stacked & Staggered Vias

Stacked and staggered vias represent advanced high density interconnect solutions for multilayer flexible pcbs, enabling efficient interlayer connectivity while preserving mechanical flexibility.

- Stacked Vias: Vertically aligned vias traversing multiple layers (e.g., layer 1→layer 3→layer 5), maximizing spatial efficiency. Ideal for 8+ layer flexible pcbs, reducing board area by 40% compared to traditional through-hole via architectures.

- Staggered Vias: Offset via placement across layers (e.g., layer 1→layer 2, layer 3→layer 4), distributing mechanical stress to enhance flexibility and resistance to cyclic bending. Optimized for dynamic applications requiring repeated deformation.

- Compliance Standards: Both configurations adhere to IPC-6013, which mandates hole wall quality, plating uniformity, and mechanical strength to ensure long-term reliability in harsh operating environments.

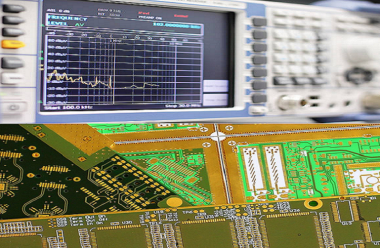

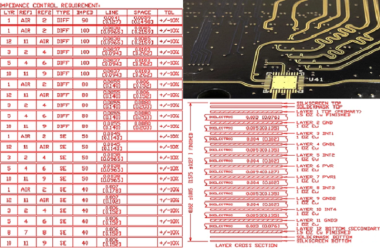

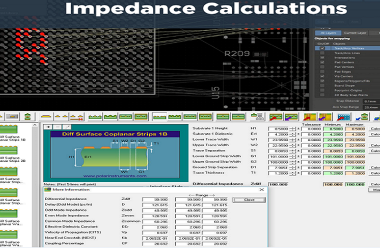

Controlled Impedance—Preserving Signal Integrity

Controlled impedance is a critical design parameter for flexible printed circuits deployed in high-speed or high-frequency applications. It ensures consistent signal propagation velocity, minimizes reflections, and mitigates electromagnetic interference (EMI), which is essential for reliable data transmission in precision electronics.

- Technical Specifications:

- Impedance ranges: 50Ω (RF/microwave applications), 75Ω (video signal paths), and 100Ω (differential pairs), with a tolerance of ±10% per IPC-2223.

- Design Variables: Trace width, substrate thickness, copper weight, and dielectric constant (εr = 3.0–3.8 for polyimide) are precisely calibrated to achieve target impedance values.

- Validation Protocols: Flexible printed circuit manufacturers utilize electromagnetic simulation tools (e.g., finite element analysis) to optimize controlled impedance profiles and conduct time-domain reflectometry (TDR) testing to verify performance against design specifications.

- Application Relevance: Critical for 5G transceivers, aerospace avionics, and high-speed data links (up to 10Gbps), where signal degradation can result in system failure or performance degradation. Controlled impedance ensures the flexible printed circuit maintains signal integrity even under extreme bending or temperature fluctuations.

How It Works—Operational Mechanics of a Flexible Printed Circuit

A flexible printed circuit functions by routing electrical signals through precision-etched copper traces on a flexible dielectric substrate, leveraging advanced manufacturing and design principles to balance mechanical flexibility, High Density, and electrical performance. The operational framework is defined by the following key mechanisms:

- Signal Propagation: Electrical signals traverse copper traces (9–140μm thickness) etched onto the polyimide substrate, with controlled impedance design ensuring consistent propagation velocity and minimal signal distortion.

- Interlayer Connectivity: via-in-pad, stacked, or staggered vias facilitate signal transfer between layers in multilayer flexible pcbs, enabling high density interconnect without compromising mechanical flexibility.

- Mechanical Adaptation: The polyimide substrate’s inherent flexibility allows the board to conform to complex shapes, with trace geometries (curved routing vs. right angles) optimized to distribute stress and prevent fatigue failure.

- Environmental Protection: A polyimide coverlay provides primary protection against moisture, particulate contamination, and short circuits, while solder mask (where specified) ensures reliable component solder joint formation.

- Component Integration: Surface-mount devices (SMDs) are soldered to precision-machined pads (often incorporating via-in-pad technology) for high-density assembly, with selective stiffeners added to support heavy components or connector interfaces.

Benefits & Applications of Flexible Printed Circuits

The integration of Flexibility, High Density, Miniaturization, and advanced features (via-in-pad, controlled impedance) delivers quantifiable technical and operational benefits across diverse industries. Below are the core advantages and targeted application domains:

Core Technical & Operational Benefits

- Spatial Efficiency: Reduces device enclosure volume by 40–60% and eliminates discrete wiring harnesses, simplifying assembly and reducing points of failure.

- Weight Optimization: 70% lighter than rigid PCBs, improving fuel efficiency (aerospace/automotive) and user comfort (wearables) while maintaining structural integrity.

- Reliability Metrics: Withstands 100,000+ cyclic bending cycles, vibration (20g, 10–2000Hz), and temperature extremes, reducing field failure rates by 50% compared to traditional wiring systems.

- Design Versatility: Enables conformal integration with irregular shapes and dynamic components, unlocking innovations such as foldable displays and minimally invasive medical tools.

- Cost-Effectiveness: Lowers assembly time by 30% (eliminating harness routing) and reduces component count via high density interconnect, delivering 15–25% total cost savings over rigid PCB assemblies.

Targeted Application Domains

- Consumer Electronics: Foldable smartphones (double-sided flexible pcbs with controlled impedance), true wireless earbuds (miniaturized single-layer flexible circuit boards), and smartwatches (bendable circuit board conforming to ergonomic contours).

- Automotive Electronics: EV battery management systems (thick-copper flexible pcbs with via-in-pad), advanced driver-assistance systems (ADAS) sensors (high density interconnect flexible circuits), and infotainment modules (bendable circuit boards adapting to dashboard geometries).

- Aerospace & Defense: Avionics control panels (multilayer flexible pcbs with stacked vias), satellite communication systems (high-temperature flexible printed circuits), and radar modules (controlled impedance flexible pcbs).

- Medical Devices: Implantable pacemakers (miniaturized flexible printed circuit boards), surgical robotics (bendable circuit boards for articulating arms), and diagnostic sensors (high density interconnect flexible pcbs for compact form factors).

- Industrial Automation: Robotics (flexible pcbs for moving joints), IoT edge sensors (miniaturized flexible circuit boards), and industrial control panels (large-format flexible pcbs with high density interconnect).

Flexible Printed Circuit vs. Rigid PCB: Technical Comparison

| Metric | Flexible Printed Circuit (Flexible PCB) | Rigid PCB |

|---|---|---|

| Mechanical Flexibility | Repeated bending/folding (100,000+ cycles) | Inflexible; fracture-prone under bending |

| Thickness Range | 0.08–0.5mm (single/multilayer) | 1.6–6.0mm (standard FR-4) |

| Weight Density | 0.2–0.5g/cm² | 1.0–1.5g/cm² |

| Component Density | Up to 200 components/cm² (HDI-enabled) | Up to 70 components/cm² |

| Via Technologies | via-in-pad, stacked/staggered microvias | Primarily through-hole vias (≥200μm) |

| Volumetric Efficiency | 40–60% space savings vs. rigid assemblies | No spatial advantage for dynamic designs |

| Target Applications | Dynamic/miniaturized electronics | Static, fixed-position systems |

FAQs About Flexible Printed Circuits

What Is the Technical Distinction Between Flexible PCB and Rigid-Flex PCB?

A flexible pcb features a fully bendable architecture, while a rigid-flex PCB integrates flexible and rigid segments. Rigid-flex designs utilize flexible printed circuit sections for dynamic interfaces and rigid substrates for component mounting, balancing flexibility with mechanical stability for hybrid assemblies.

How Do Flexible Printed Circuit Manufacturers Ensure Quality Compliance?

Flexible printed circuit manufacturers adhere to IPC-2223 (design), IPC-6013 (performance), and IPC-A-600F (acceptability) standards. Quality control protocols include TDR testing (controlled impedance validation), cyclic bend testing, and automated optical inspection (AOI) for trace defects.

Can Flexible Printed Circuits Operate in High-Temperature Environments?

Yes—high-temperature flexible pcbs utilize advanced polyimide substrates and thermally stable adhesives, supporting continuous operation up to 300°C. These variants are specified for automotive engine compartments, aerospace systems, and industrial thermal processing equipment.

What Is the Maximum Layer Count for a Flexible Printed Circuit?

Qualified flexible printed circuit manufacturers offer up to 16-layer configurations with high density interconnect, via-in-pad, and stacked vias. These designs are deployed in complex applications such as medical implants and 5G base station transceivers.

What Criteria Define a Qualified Flexible PCB Manufacturer?

A reputable flexible pcb manufacturer demonstrates industry-specific expertise (e.g., medical, aerospace), compliance with IPC standards, and technical capabilities for advanced features (via-in-pad, controlled impedance, high density interconnect). Validation through sample performance testing is recommended to verify adherence to application requirements.

Conclusion

A flexible printed circuit—whether designated as flexible pcb, flexible circuit board, or bendable circuit board—is a technologically advanced interconnection solution that synthesizes Flexibility, High Density, and Miniaturization to address modern electronic design challenges. Advanced features including via-in-pad, stacked/staggered vias, and controlled impedance enable high density interconnect, making it indispensable for miniaturized, dynamic devices across consumer electronics, automotive, aerospace, and medical sectors.

Flexible printed circuit manufacturers play a pivotal role in delivering reliable, high-performance solutions, adhering to rigorous industry standards to ensure consistency and durability. By leveraging the inherent benefits of flexible pcbs—spatial efficiency, weight reduction, design versatility, and enhanced reliability—engineers can develop innovative products that exceed the limitations of rigid PCBs. As technological demands evolve, flexible printed circuits will continue to advance, with trends such as eco-friendly substrates, integrated sensor integration, and ultra-high density interconnect driving adoption. Whether designing foldable displays, implantable medical devices, or 5G infrastructure, the flexible printed circuit remains the definitive solution for unlocking smaller, lighter, and more capable electronic systems.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)