How to Implement AI in Electronics Manufacturing: A Step-by-Step Guide for EMS and Contract Manufacturing Excellence

Electronics manufacturing is evolving rapidly, with electronic manufacturing companies racing to meet higher quality standards and faster delivery demands. For electronics manufacturing services, ems manufacturing, and contract electronics manufacturing providers, integrating AI is no longer optional but a core requirement to stay competitive. This guide breaks down actionable steps to implement AI across electronics manufacturing workflows, covering ems electronic manufacturing, box build assembly, and box build processes, while aligning with industry standards to drive tangible value for ems manufacturing services and ems contract manufacturing partners. The following framework balances technical feasibility and practical scalability, addressing real challenges in design, production, and quality control for electronic contract manufacturing services and electronic manufacturing teams.

Lay the Foundation: Align AI Implementation with Electronics Manufacturing Core Needs

Before deploying any AI solution, alignment with core workflows of electronics manufacturing and electronic manufacturing is critical to avoid disconnected investments. Many ems electronics providers fail here, wasting resources on tools that do not solve actual production bottlenecks. The foundation phase focuses on defining clear objectives tied to key processes for electronics manufacturing services, ems manufacturing, and contract electronics manufacturing operations.

Map Key Workflows for Targeted AI Integration

Focus on high-impact workflows where AI delivers measurable results, prioritizing pain points that cause delays, defects, or cost overruns for ems manufacturing services and box build assembly teams

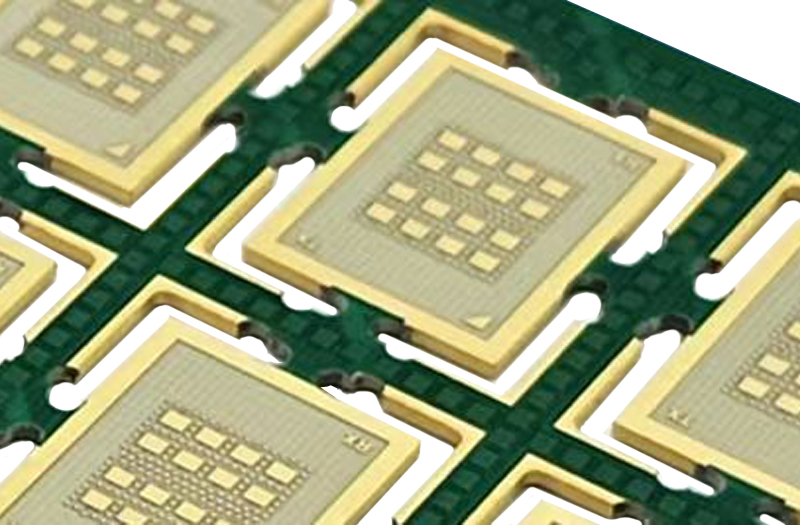

- PCB design and prototyping: Resolve layout errors and compliance gaps that lead to costly reworks in ems electronic manufacturing

- SMT and component placement: Fix precision issues and high reject rates in electronics manufacturing production lines

- Quality inspection: Eliminate manual inspection limitations for box build and contract electronics manufacturing batches

- Predictive maintenance: Reduce unplanned downtime for critical equipment in electronic contract manufacturing services

- Box build assembly: Streamline multi-component integration for complex products in ems contract manufacturing

Define Compliance & Standard Alignment

AI implementations must align with industry standards to ensure compatibility and reliability for electronic manufacturing companies. Two core standards govern electronics manufacturing and ems manufacturing workflows:

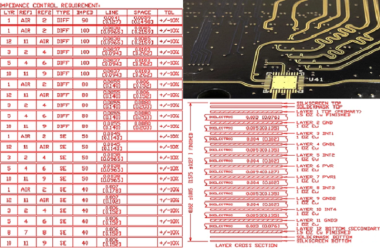

- IPC-2221: This standard specifies general design standards for printed boards, requiring strict control of trace width, spacing, and layer stackup. AI tools for PCB design must auto-verify these parameters, ensuring Class 2 (industrial) and Class 3 (aerospace/medical) compliance for electronics manufacturing services

- IPC-6012: The qualification and performance specification for rigid printed boards mandates consistent material and process quality. AI-powered process monitoring must track variables like lamination pressure and temperature to meet IPC-6012’s reliability benchmarks for ems electronics and electronic manufacturing

Assess Infrastructure Readiness for AI Deployment

AI relies on real-time data, so electronics manufacturing and ems manufacturing facilities need basic connectivity and data capture capabilities

- Ensure 99.9% device connectivity for SMT machines, AOI systems, and box build assembly lines to collect consistent data

- Deploy edge computing nodes for low-latency AI processing, critical for real-time decisions in box build and contract electronics manufacturing

- Establish a unified data format to integrate data across electronics manufacturing services, ems contract manufacturing, and electronic contract manufacturing services workflows

Deploy AI for Core Electronics Manufacturing Workflows (Step-by-Step)

Once the foundation is set, deploy AI across core workflows in phases, starting with high-ROI use cases. This phased approach minimizes disruption and allows for iterative optimization, ideal for ems manufacturing, electronic manufacturing, and electronics manufacturing services teams transitioning to smart operations.

AI for PCB Design Optimization (Solve Design-to-Production Gaps)

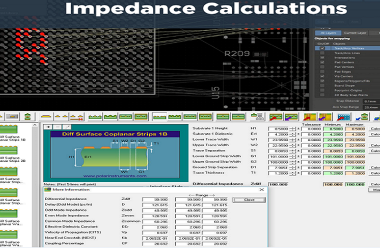

PCB design errors are a top cause of delays in electronics manufacturing, with 30% of prototyping reworks stemming from non-compliant layouts. AI addresses this by automating compliance checks and performance optimization for ems electronics and ems electronic manufacturing projects

- Integrate AI-driven design checkers to auto-validate IPC-2221 standards: Verify trace width, spacing, and via placement in real time, flagging non-compliant elements before prototyping

- Deploy AI thermal simulation tools: Predict heat distribution across PCB layouts, optimizing component placement to reduce overheating risks by 40% for high-power electronic manufacturing products

- Leverage AI for DFM (Design for Manufacturability) analysis: Identify layout issues that hinder SMT placement or box build assembly, cutting design-to-production lead time by 25% for contract electronics manufacturing orders

AI for Smart Production in EMS Manufacturing & Electronics Manufacturing

Production lines in ems manufacturing and electronics manufacturing services face constant pressure to balance speed and precision, especially for high-mix low-volume orders. AI optimizes production scheduling, process control, and resource allocation to boost efficiency

AI-Powered Production Scheduling

Manual scheduling leads to 15-20% capacity waste in electronic manufacturing companies. AI solves this by adapting to real-time changes

- Input variables: Order priorities, material availability, machine capacity, and box build assembly requirements for ems contract manufacturing

- AI algorithms generate dynamic schedules that reduce changeover time by 30% for electronics manufacturing services and ems manufacturing lines

- Auto-adjust schedules for material delays or machine breakdowns, keeping on-time delivery rates above 98% for electronic contract manufacturing services

AI for Real-Time Process Control (SMT & Component Placement)

SMT placement precision directly impacts electronics manufacturing quality, with even 0.05mm deviations causing defects. AI enhances process stability for ems electronics and electronic manufacturing

- Deploy AI vision systems to monitor component placement accuracy, detecting misalignment in 0.02 seconds with 99.9% precision

- Auto-adjust placement parameters based on component type and PCB layout, reducing defect rates by 55% for ems electronic manufacturing

- Track solder paste deposition in real time, aligning with IPC-J-STD-001 standards to ensure consistent joint quality for contract electronics manufacturing

AI for Quality Control: Zero-Defect Targets in Electronics Manufacturing

Quality control is non-negotiable for electronics manufacturing services and ems manufacturing, as a single defect can lead to costly recalls for electronic manufacturing companies. AI replaces manual inspection with faster, more accurate solutions for box build and box build assembly

- AI-Powered AOI/AXI Inspection: Automate defect detection for PCBs and assembled components, covering open circuits, short circuits, and component misalignment

- Inspect 200+ components per second with 99.8% accuracy, 10x faster than manual checks for ems manufacturing services

- Classify defects by severity, auto-triggering rework workflows for critical issues in electronic contract manufacturing services

- AI for Root Cause Analysis: Link defects to specific process variables (e.g., solder temperature, component batch)

- Analyze historical data to identify recurring issues, cutting corrective action time by 60% for electronics manufacturing and ems electronics

- Auto-update process parameters to prevent repeat defects, improving first-pass yield by 18% for box build assembly

- AI-Driven End-to-End Traceability: Create a digital thread for every product in contract electronics manufacturing

- Track components from incoming inspection to box build completion, enabling full traceability in 3 seconds for compliance audits

- Auto-generate compliance reports aligned with IPC standards, simplifying audits for ems contract manufacturing and electronic manufacturing

Optimize AI for Box Build Assembly & End-to-End EMS Manufacturing

Box build assembly is a complex phase for electronics manufacturing services, involving integrating PCBs, cables, enclosures, and peripherals. AI streamlines this process, ensuring consistency for ems manufacturing services and ems contract manufacturing partners. Meanwhile, end-to-end optimization unifies AI tools across the entire workflow to maximize value.

AI for Streamlined Box Build Assembly

Box build assembly often involves custom configurations, leading to variability in electronic manufacturing. AI standardizes workflows and reduces human error for box build projects

- AI-guided assembly: Provide step-by-step visual prompts to operators, reducing assembly errors by 70% for complex box build assembly

- Auto-verify component compatibility: Cross-check parts against BOMs in real time, eliminating wrong-component issues for ems electronics and contract electronics manufacturing

- AI-powered torque control: Ensure consistent fastening for enclosures and connectors, meeting IPC mechanical stability standards for electronics manufacturing services

Unify AI Tools for End-to-End EMS Manufacturing Efficiency

Disconnected AI tools create silos for electronic manufacturing companies, limiting visibility across ems manufacturing and electronics manufacturing workflows. Unification drives holistic optimization

- Integrate AI design, production, and quality tools into a single platform for ems manufacturing services

- Enable data sharing between PCB design, SMT production, and box build assembly, reducing handoff delays by 35% for ems electronic manufacturing

- Use AI to generate cross-workflow insights, identifying how design choices impact production efficiency for electronic contract manufacturing services

AI for Supply Chain Synergy in Contract Electronics Manufacturing

Supply chain disruptions are a top challenge for contract electronics manufacturing and ems contract manufacturing. AI mitigates risks by predicting issues and optimizing inventory

- AI demand forecasting: Predict order volumes for electronics manufacturing services, reducing inventory holding costs by 22%

- AI supplier risk assessment: Identify potential delays from component suppliers, allowing proactive alternative sourcing for ems manufacturing

- Auto-adjust production plans for material shortages, minimizing downtime for electronic manufacturing and box build assembly

Validate, Scale & Sustain AI Implementation in Electronics Manufacturing

Successful AI implementation requires validation against key metrics, scalable deployment, and ongoing maintenance to deliver long-term value for electronics manufacturing, ems manufacturing, and electronic manufacturing companies. This phase ensures AI solutions evolve with changing demands for electronics manufacturing services and contract electronics manufacturing.

Validate AI Performance with Quantifiable Metrics

Measure success against metrics tied to core goals, ensuring AI delivers tangible value for ems electronics and ems manufacturing services

- Efficiency metrics: Production throughput increase (target 20-30%), changeover time reduction (target 25-35%), box build assembly cycle time reduction (target 20%)

- Quality metrics: First-pass yield improvement (target 15-20%), defect rate reduction (target 50-60%), compliance pass rate (target 100% for IPC standards)

- Cost metrics: Labor cost reduction (target 10-15%), rework cost reduction (target 40-50%), unplanned downtime reduction (target 30-40%)

Scale AI Across Electronics Manufacturing Operations

Once validated in pilot workflows, scale AI to cover all critical processes for electronic manufacturing and ems contract manufacturing

- Prioritize scaling to high-volume lines first: Deploy AI to top-performing electronics manufacturing services and ems manufacturing lines to maximize ROI quickly

- Standardize AI deployment protocols: Create repeatable processes for onboarding new lines, reducing implementation time by 40% for box build and contract electronics manufacturing

- Train cross-functional teams: Ensure design, production, and quality teams can operate and optimize AI tools, reducing reliance on specialized technicians for ems electronic manufacturing

Sustain AI Value with Ongoing Optimization & Maintenance

AI models degrade over time without updates, so ongoing maintenance is critical for long-term success in electronics manufacturing and electronic manufacturing

- Update AI models monthly with new production data: Adapt to component changes, process adjustments, and new IPC standard updates for electronics manufacturing services

- Perform quarterly AI system audits: Ensure tools remain aligned with business goals for ems manufacturing services and ems contract manufacturing

- Monitor AI compliance: Verify continued alignment with IPC-2221, IPC-6012, and other industry standards for contract electronics manufacturing and box build assembly

Key Outcomes of AI Implementation for Electronics Manufacturing & EMS Partners

Implementing AI transforms electronics manufacturing, electronic manufacturing, and ems manufacturing operations, delivering competitive advantages for electronics manufacturing services, ems electronics, and electronic contract manufacturing services providers. The following outcomes highlight the tangible value for box build, box build assembly, and contract electronics manufacturing teams.

- Boost production efficiency by 25-30% while improving quality consistency, meeting the strict demands of ems contract manufacturing clients

- Cut time-to-market by 20-25% for new products, critical for electronic manufacturing companies competing in fast-paced markets

- Reduce operational costs by 15-20% through optimized resource use and reduced waste, enhancing profitability for electronics manufacturing services

- Achieve 100% compliance with IPC standards, reducing audit risks for ems manufacturing and contract electronics manufacturing

- Enhance scalability for high-mix low-volume orders, a key differentiator for ems electronic manufacturing and box build assembly providers

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)