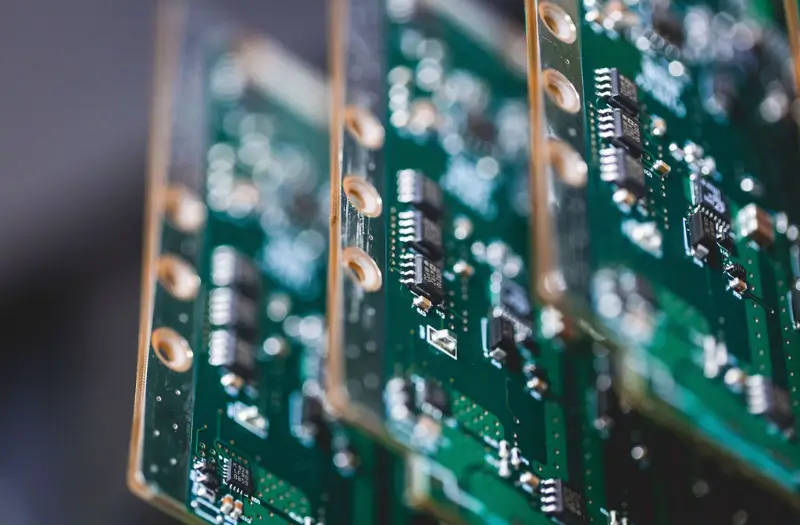

In today’s world of advanced electronics, cutting-edge technology, miniaturization, and ever-increasing signal speed, choosing the right type of printed circuit board material is incredibly important.

There are a variety of materials to choose from to support your design performance requirements, starting at the bottom with FR-4, through a wide array of high speed materials between FR-4 and Teflon.

Printed circuit boards are only as good as the materials they’re made from, which means the right high-quality materials will result in a circuit board that not only works properly, but also lasts for the expected lifespan of the product.

Select the incorrect materials and, simply put, your PCB — and the product in which it lives — may not work as designed.

In our comprehensive guide, discover the most common types of materials and key considerations you shouldn’t forget when making selections for your next project.In today’s world of advanced electronics, cutting-edge technology, miniaturization, and ever-increasing signal speed, choosing the right type of printed circuit board material is incredibly important.

There are a variety of materials to choose from to support your design performance requirements, starting at the bottom with FR-4, through a wide array of high speed materials between FR-4 and Teflon.

Printed circuit boards are only as good as the materials they’re made from, which means the right high-quality materials will result in a circuit board that not only works properly, but also lasts for the expected lifespan of the product.

Select the incorrect materials and, simply put, your PCB — and the product in which it lives — may not work as designed.

In our comprehensive guide, discover the most common types of materials and key considerations you shouldn’t forget when making selections for your next project.

Basic PCB Construction

Circuit board and flex materials are selected around electrical and environmental properties required to operate based on the schematic. The schematic dictates the number of layers and the form factor of the board. Typically, a board supplier will provide a stackup of the selected materials based on your design. This could be a number of layers — not just 4.

Substrate: This refers to the supporting material used in a PCB that holds the components and traces.

Copper: This highly conductive element is used to make the signal traces that conduct electricity.

Solder mask: This is a technique in which all parts of a circuit board are coated with epoxy except the contacts to be soldered, the gold-plated terminals of any card-edge connectors, and fiducial marks.

Silkscreen: The ink is digitally printed and doesn’t impact the function of a PCB, but it’s an equally important part of a PCB’s construction. Also known as a “silkscreen legend,” this refers to the decals and reference designators in epoxy ink printed on a PCB. A silkscreen will help you recognize warning symbols and identify components and where they are to be placed. A silkscreen will also identify test points and manufacturer marks and more. The ink is typically white, and black may also be used at times when the substrate is white in color.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)

![Determining PCB Via Size [w Guidelines] Determining PCB Via Size [w Guidelines]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Determining-PCB-Via-Size-w-Guidelines-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)

![PCB Material Types Explained [Your Guide] PCB Material Types Explained [Your Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/PCB-Material-Types-Explained-Your-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)