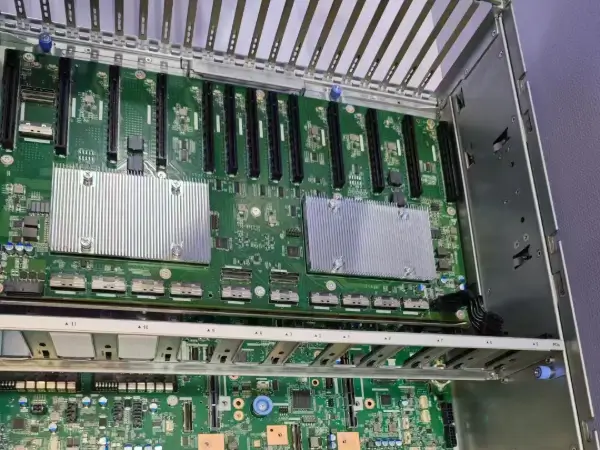

- PCB assembly or Box build assembly service delivers a PCBA or a complete electronics assembly in a box

- Providing end-to-end solutions for PCB Assembly or Electronic Manufacturing Services

Box Build Assembly - Electronics Manufacturing

Manufacturing involves many moving parts and coordination among multiple vendors. However, when you’re making the move to scale or you’ve decided its time to put a board into volume production, certain manufacturers can offer multiple services to help you reduce the logistical workload. One of these service levels is a box build assembly service, where the manufacturer delivers a complete electronics assembly in a box that is immediately ready to use.

A box build assembly service isn’t the right path for all products, and different electronics manufacturers have varying capabilities in this area. Some offer a complete package while others require working with a vendor or partner to coordinate all aspects of the design package.

What is a Box Build?

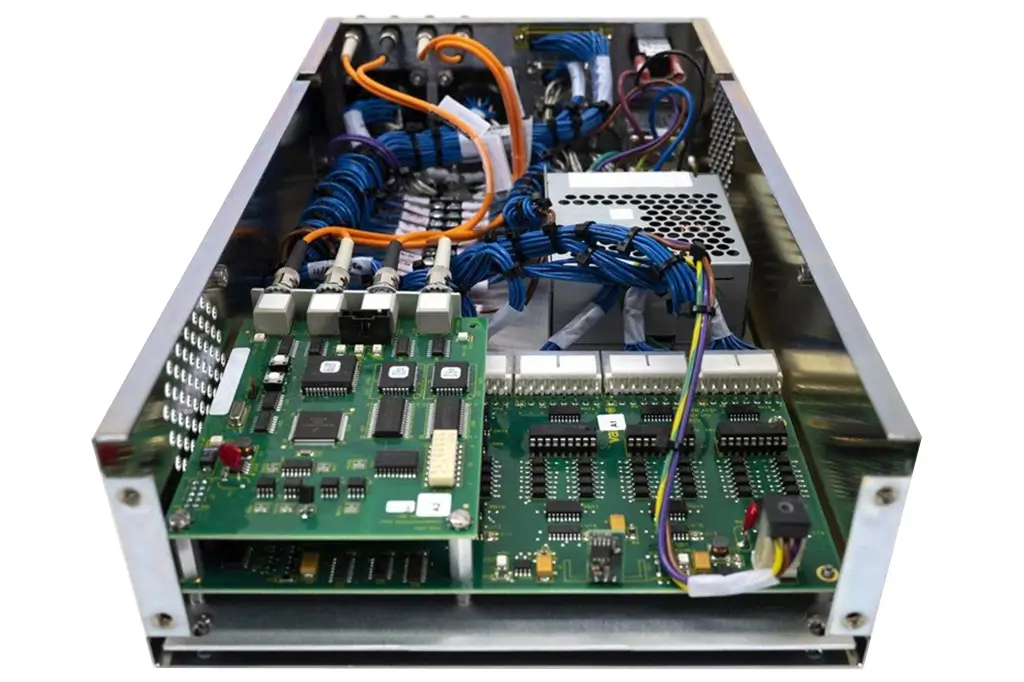

If you look at a manufacturer’s website, they will sometimes describe a box build assembly as a system integration, meaning they try to bring as many parts of the system into the assembly as possible. Box build assembly involves assembling both the PCBA and the “box” (or enclosure) in which the product will be packaged. These assemblies are an option for volume production after the board has been prototyped, tested, tested for EMC, and and qualified against any other relevant regulations.

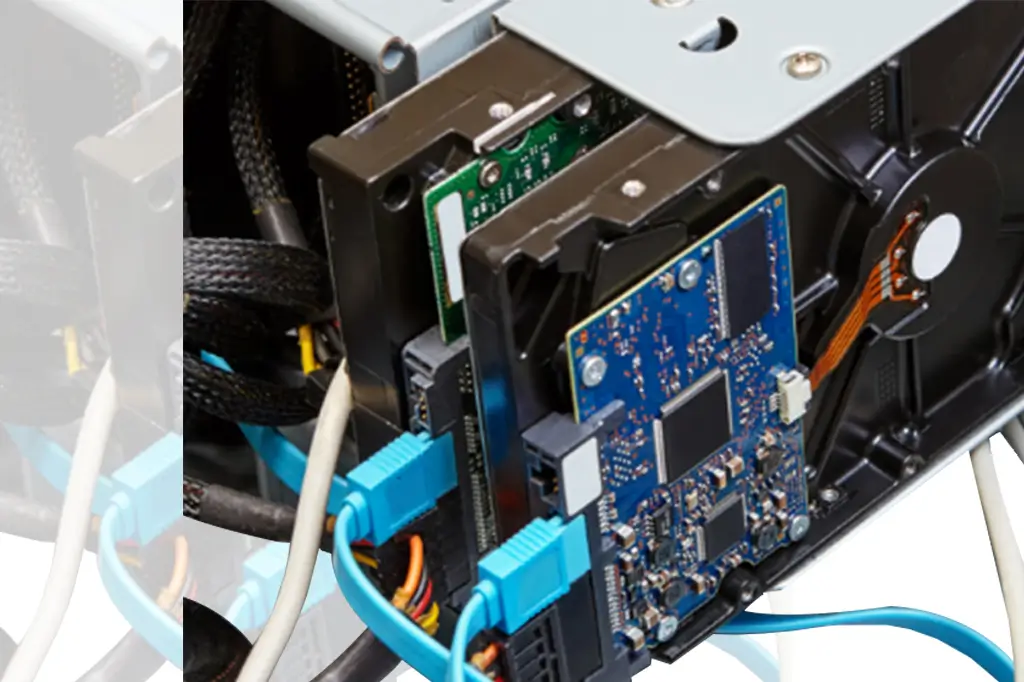

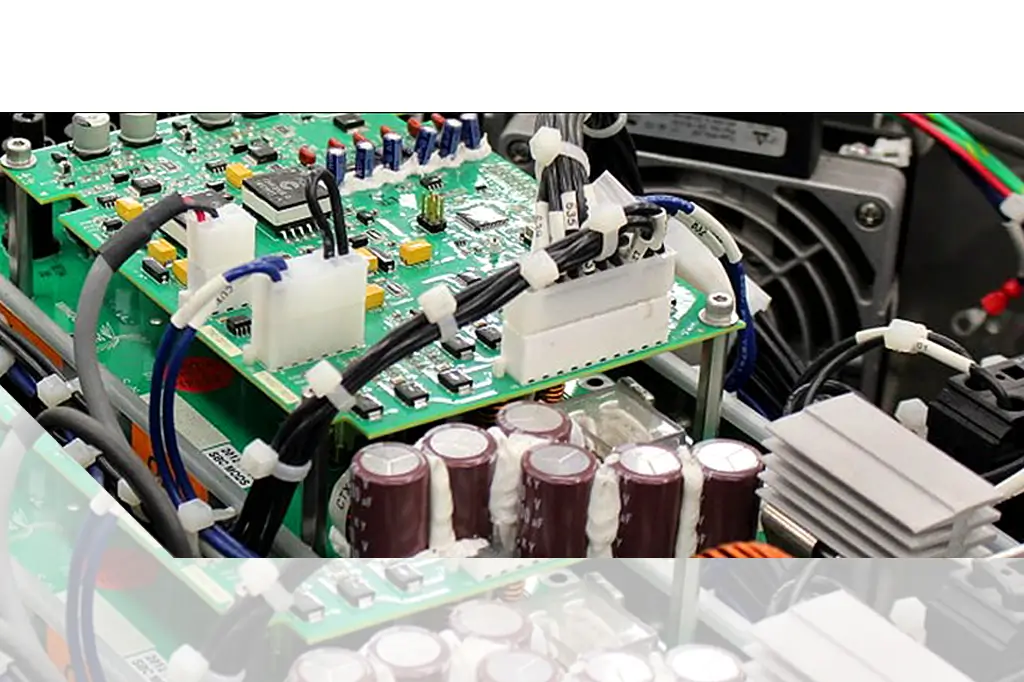

Some of the components that go into a box build include:

- Connectors, including modular connectors like D-shells

- Custom cable assemblies and wiring harnesses

- Batteries, either as the main or backup power source

- A custom or off-the-shelf enclosure

- Heat sink attachments with a thermal interface material

- Other attachments to the board, like brackets or standoffs

- Other attachments to the enclosure, such as fans

Different manufacturers offer different capabilities and service levels in these areas. Some of these components may need to be procured from vendors or partners, while some can be purchased off-the-shelf. As a designer, it’s important to work with the assembler to determine which of these components needs to be procured from a distributor and which can be custom-built.

Box Build Manufacturers

Electrical manufacturing is a competitive market, but our passion for a fast turnaround and happy customers from concept to delivery stands out like none other. We hope to continue to provide a professional service to the highest standards. Every component of your new box build will remain in house; from receipt of design to distribution, we’ll take care of it all. This includes:

- Small box builds to large scale projects

- Subassemblies

- Designed to print

What is Included in a Box Build Assembly?

A box build assembly always comes in an enclosure which comprises assembled PCBs with electronic components, power supply components, wiring harnesses, mechanical parts, software, cooling and ventilation systems, connectors, sensors, peripheral devices, and more. However, this is a generic description of what all a box build assembly may include. The specifics depend on the client requirements. At Benchuang, we understand your requirements, analyze, and decide the inside contents of a box build. We ensure system compatibility with the mechanical parts.

Box Build Assembly Capabilities

The following capabilities of Benchuang make us one of the most reputed service providers for box build services.

- Cable assemblies

- Complete wire harness assemblies

- Electromechanical assemblies (Mechatronics)

- Component procurement (Resource management)

- Printed Circuit Board Assemblies (PCBA)

- Front Panel Assemblies

Turnkey Box Build Assembly Process

At Benchuang, we understand the importance of attention to detail for success in electronic manufacturing. From the start of each project to its final shipment, our team strives to raise the bar for quality and value in everything we do. As your box build assembly partner, we will ensure that we deliver the exact results you want. Our team has experience with quick-turn deliveries, specific drop shipments and other project delivery methods.

Each project begins with a detailed consultation in which we take the time to learn your business and tailor our services accordingly. In this consultation, we can also offer you a free quote to help you understand how much the box build PCB assembly services will cost and why. This stage is an excellent way to figure out your needs and develop a solution that exceeds your expectations.

After the consultation stage, we’ll take care of the rest. Based on your needs, we’ll design and source the required materials. Next, we’ll install these cables, sub-assembly components and wiring harnesses through soldering and other processes.

After the PCB has been assembled, we then place the circuit board in a custom-designed enclosure to provide clients with a product ready to use immediately. During this stage, a prototype PCB and enclosure can be created and then sent to the client to see if it meets their needs, with Benchuang adjusting it as needed based on client feedback. We can also load design software and configure the system for use.

At Benchuang, we know how important it is to have reliable and functional products. Before we deliver the final product to your door, we’ll perform highly-detailed testing and inspection services to ensure we’re giving you only the best. In this process, we’ll begin with a visual inspection, but we may also include in-circuit testing, functional testing and automated optical inspection.

Once the inspection clears the product, we’ll handle the packing and labeling products, getting them wherever you need quickly.

Box Build Assembly Files request

Every box build assembly involves a unique process that depends on the client’s specifications. To understand your project requirements, your assembly partner may request these documents:

- Bill of materials: Your project’s bill of materials includes some of the most important information for the box build assembly process, including the project’s components and materials.

- 3D CAD model: A 3D CAD model of your project provides your assembly partner with a visual overview of your desired results. Many companies also have CAD packages that allow them to use CAD drawings in the assembly process.

- Product dimensions: Your unit’s size and weight influence your assembly partner’s handling, storage and shipping procedures. This information helps them complete the box build assembly process more efficiently.

- Prototype unit: Sample units provide your partner with visual and physical information about your intended results. If you don’t have a CAD drawing of your project, some companies can develop a design based on a prototype.

- Testing use cases: Consider providing your partner with testing use cases. Most companies can help develop use cases for your product testing. If you have electrical testing knowledge, you could also create your own use cases.

- Shipping information: By determining how to package and ship your product before building, you give your assembly partner important information. Your packaging and shipping information influences how the company will complete the other steps in the process.

Box Build Assembly Services Benefit

Here are some benefits of partnering with a box build assembly services provider for your electronics requirements.

- Developing and maintaining an entire electromechanical system in-house requires specific skills and expertise, equipment, and physical space. Also, one may require significant investment. Dedicated box build assembly services providers have technology expertise and are equipped to deliver according to your requirements. This saves both time and cost.

- At Benchuang, we have the capability to take on complex projects and deliver them efficiently as we have all the required capabilities. We help save your cycle times and reduce the time-to-market for your product.

- Once you rely on your services partner, you can focus on your core competencies and save the overhead costs for some other projects. You can build your product design, focus on marketing campaigns, increase sales revenues, and more.

- At Benchuang, we have the expertise in cutting edge technology and equipment which helps us enhance the quality and performance of the assembly.

- Box build assemblies are flexible, and you can scale up or scale down production based on your business requirements. You do not need any additional equipment or layoff people at times when the business demand is low.

- As an OEM of electromechanical products and systems, you may not be aware of the legal details, regulatory compliance, equipment maintenance and so on. As a box build assembly services provider, we have the knowledge and experience pertaining to regulatory compliance and industry standards, equipment maintenance, and so on.

- We also offer custom options and prototyping which is beneficial in product development stages.

Choose the Right Box Build Assembly Services

Every assembly partner takes a different approach to the box build process. The right company for your project will have the experience, capabilities and certifications to meet and exceed your requirements.

When searching for box build assembly services, consider these factors:

- Industry-specific needs: Does the company meet critical standards in your industry such as FDA regulations?

- Turnaround time: How quickly can they deliver results, especially in quick-turn deliveries?

- Proximity: How close is the facility operate to your company and your customers?

- Equipment: Does the facility have advanced equipment that can create accurate and efficient results?

- Ethical practices: If your business has ethical considerations, does your assembly partner operate in line with those ethics?

- Custom capabilities: What types of custom capabilities can the partner offer to your company?

- Communication: Does the company clearly and frequently communicate with you during the box build assembly process?

Electronics Manufacturing Services

Electronics Manufacturing Services (EMS) applies to the entire industry as well as to a specific class of subcontractors or companies. It is often used interchangeably with the term Contract Manufacturing Services (CMS) or Contract Electronics Manufacturing (CEM). Electronics Manufacturing companies provide a very broad range of manufacturing and accompanying services, such as supply chain management, engineering and product management support, as well as after sales support. Designed especially for OEMs, the services of EMS providers allow manufacturers to focus on their core business, i.e., product research and development, as well as sales and marketing of their devices.

What is Electronic Manufacturing Services? Why should you considering outsourcing the manufacturing of your product? Is there a difference between Electronic Manufacturing Services and Contract Manufacturing? Do Tier 1 Electronic Manufacturing Services actually have more capabilities than Tier 2 and 3 companies? These questions are often heard in the Electronics industry. As an industry leader, we thought we would give a few hints and elaborate on the industry we work in, daily.

The Electronic Manufacturing industry has been evolving quite a lot of the last 18 years. With the double digit growth impulsed by the rise of connected devices and connectivity overall, Electronic Manufacturing Services (EMS) providers will play an ever increasingly important role in the Electronics value chain.

Electronics manufacturing services (EMS) is a term used for companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers (OEMs). The concept is also referred to as electronics contract manufacturing (ECM).

According to Market Research, the following are the key factors driving the Electronics Manufacturing Services (EMS) market

- Increasing interest in automobile electronics- The increase is attributable to the need for safety solutions.

- Increasing interest in consumer electronics- According to a recent Frost & Sullivan report, the tendency towards outsourcing will intensify as consumer electronics demand rises.

- Concentration on basic capabilities and advanced skills- Companies are looking for solution providers with knowledge of their particular industry or market segment.

- Proliferation of mobile technology- The markets for iPhones, Android phones, and wearable technologies are expanding.

Trends and Opportunities in the Electronics Manufacturing Sector (EMS)

One of the global businesses with the quickest growth and most continual change is electronics manufacturing. Due to technological developments and rising consumer demand for electronic gadgets, this industry is primed for expansion and is full of potential for both businesses and investors.

- Growing Demand for Smart Devices– Smartphones, smartwatches, and smart home gadget demand has risen in recent years, and it is anticipated that this trend will continue in the years to come. The market for smart devices is anticipated to expand quickly as a result of the Internet of Things (IoT), providing enormous opportunities for electrical makers. Companies will succeed in this market if they can provide high-quality, cutting-edge products that satisfy consumers’ shifting requirements and desires.

- An Increase in Wearable Technology- Another development that will revolutionize the electronics manufacturing sector is wearable technology. The prevalence of wearable technology is rising, and its expected that this trend will continue. Smartwatches, virtual reality headsets, and activity trackers are a few examples. The market for wearable technology is anticipated to expand as technology advances and costs drop-down, offering enormous opportunities for electronic makers.

- 5G Technology’s Development- The newest advancement in telecoms, 5G technology, is anticipated to fundamentally alter how electronic products are created, assembled, and used. This technology is expected to result in a new generation of gadgets that are more potent and effective because of their capacity to speed up data transmission, reduce latency, and increase dependability. Businesses that can design and produce products that work with 5G technology will have a significant competitive edge.

- Growth of E-Commerce- Another trend that is anticipated to continue growing is e-commerce, and its rise is anticipated to fuel the need for electronic gadgets. The demand for gadgets that make buying simpler, such as smartphones and laptops, is anticipated to rise as more consumers switch to online shopping. Electronic producers will have a great chance to design and produce novel gadgets that cater to changing customer requirements as a result of this trend.

- Increasing Use of Renewable Energy- The use of renewable energy sources like solar and wind power is rising, and it is anticipated that this trend will continue in the years to come. As more individuals select renewable energy sources to power their homes and businesses, it is predicted that demand for gadgets like solar panels and wind turbines will rise. Businesses that can develop cutting-edge goods that are suitable for renewable energy sources will have a huge competitive advantage.

The electronics manufacturing sector is a vibrant, rapidly changing industry that is set for expansion and offers several prospects for businesses and investors. Companies that can stay on top of the newest developments and provide high-quality, cutting-edge products will succeed in this market. The electronics manufacturing sector is anticipated to expand dramatically over the next several years as a result of the growth of smart gadgets, wearable technology, 5G technology, e-commerce, and renewable energy sources, offering enormous opportunities for businesses to prosper.

Challenges In Electronic Manufacturing Services Market

The EMS market has excellent future possibilities, but it also has several problems and difficulties.

- Decreased Operating Margins- The cost of electronic goods has decreased due to rising global competition and the deployment of cutting-edge technologies. The ongoing pressure from OEMs to cut costs, on the other hand, has hurt the profit margins of some EMS suppliers in particular industry sectors. As a result, manufacturers must take steps to increase production efficiency if they want to continue to be successful. These steps can include using cutting-edge technology, updating equipment, optimizing manufacturing processes, etc.

- Globally Complex Supply Chain- EMS firms must balance their internal and external resources while adhering to international standards. The operational load is further increased by traceability and compliance difficulties, as components and subassemblies are likely to move across many countries before being delivered to end users.

- Management of Supplier Quality- Taking advantage of global supply chain management is a current trend among electronics businesses, therefore finding the correct supplier is essential for success. To confirm that suppliers are dependable and professional, manufacturers must have a solid grasp of them. It would be preferable to create a system for quality control and traceability that would enable them to acquire top-notch post-production support.

- Products with Quicker Lifecycles- Short product life cycles are a result of consumers’ tastes for electronic items changing quickly. Electronics producers must be adaptable and quick to market trends to increase sales and capture market share. Create efficient NPI procedures, maintain information exchange, and foster communication across multiple departments to produce goods that satisfy customers’ expectations as soon as feasible.

- Market Ambiguity- Manufacturers have significant difficulties as a result of the market’s overall unpredictability, which is exacerbated by the cyclical nature of consumer demand and the economy’s volatility. Manufacturers must increase output in this circumstance to maintain inventories in line with demand, which is also true in the electronics manufacturing sector.

-

Adoption of New Laws and Standards- New laws and requirements must be complied with, and manufacturers must modify their products accordingly. For instance, the new legislation mandates that producers of electronic items exercise greater social responsibility and create more environmentally friendly products. Therefore, while designing and developing electrical devices, producers must consider the product’s life cycle.

Electronic Manufacturing Services Industry

The electronic manufacturing services market has been constantly growing for years. In addition to the production side, EMS companies also often offer support OEM’s in logistics management, purchasing assistance, and managing the entire supply chain. The industry is expected to grow on average at the rate 7.5% per annum in the 2018-2024 period.

The electronics industry is very wide-spread and refers to a variety of industries, including governmental (eg. security and access control applications), industrial (eg. automation, IoT), consumer (smartphones, PCs, laptops etc.), healthcare (medical devices) or automotive. The growth of the EMS industry is mainly driven by the rising demand for automotive and consumer electronics, as well that is electronics becomes more present in each and every product that we face in daily lives. This rising need for electronics and innovative technological solutions, combined with growing customer requirements, the need to control costs and trend for automation, mean that OEMs increasingly need to choose to cooperate with partners offering industry knowledge and experience in the area of manufacturing.

Electronic Manufacturing Industry – Tiers

The electronic manufacturing industry is commonly divided into tiers, which is mainly size-related. These tiers are predominantly based on revenue. The most important is that both the OEM and the EMS provider find a partner that is “best” fit for each other and match each other strategies.

On the end of the day, the reality is that electronics manufacturing companies representing Tier 3 or 4 can have exactly the same experience and competences as these from Tier 1 or 2. But it does not mean that both will provide the same quality customer service for different type of OEMs, that are also segmented into tiers. Threes and fours are simply smaller companies. But on the other hand, smaller companies frequently present more partnership approach and are more committed. It is extremely important, that a good fit is obtained and if it is – it is only when such two companies can build a beneficial partnership between each other and gain an abnormal commitment from an EMS provider.

Electronics Manufacturing Applications

From various industrial sectors up to the medical industry, more and more OEM’s are increasingly searching for electronic manufacturing services. Gone are the days when OEMs decided to work with a contractor for purely operational and strictly assembly-only reasons. Today, it is part of a well-thought-out overall business strategy.

Indeed, manufacturers have discovered that with a collaborative approach, they can achieve significant benefits that improve their customer service and quality of their products, as well as enable them to react faster to dynamic market changes. Thus, the total costs are reduced and OEMs achieve a value they would have a hard time to build on their own.

A few critical applications and their specifics that are worth having a glance at, are:

- Medical devices: OEMs from the healthcare industry look at adequate certifications (ISO 13485), as well as tight process control and above average quality standards at the electronic manufacturing provider.

- Industrial automation devices: a broad segment of devices that relate to industry-related devices, mainly used for control and automation of various processes. EMS providers supporting industrial electronics are required to be able to adequately manage high-mix low-volume production and support a variety of processes for OEMs (printed circuit board assembly, conformal coating, final assembly, electro-mechanical integration, testing).

What is High-mix low-volume (HMLV) electronic manufacturing?

A high-mix low-volume production environment refers to the setting, where assembled devices vary in the size of the production batch, production processes applied and its final application. EMS providers that offer high-mix low-volume (HMLV) electronics manufacturing services, have the capability to adapt to the conditions, where product changeovers are common and thus the EMS needs to reconfigure the assembly lines in a matter of minutes. HMLV providers can much more easily adapt to changes in requirements and are capable to react to increased demand of the Customers.

High-mix low-volume electronics manufacturing providers require very precise controls and experienced indirect resources, since various challenges they experience bring additional threats of mistakes. That is why automation, lean approach (including. SMED), yet strong software control and organized, smart factory is a key element for supporting high-mix low-volume electronics manufacturing projects.

What are the capabilities of Electronics Manufacturing Services providers?

One of the main services offered by the electronics manufacturing services providers is the Printed Circuit Board Assembly (PCBA) capabilities. Currently, the technological advancements allows a very fast and high-quality assembly, due to precise components placement capabilities. A sophisticated SMT assembly line is priced even on the level of millions of dollars, thus it may be an extremely high investment for an OEM. However, if they leverage the fact that the electronics manufacturers produce for a variety of Customers, they can gain access to a modern, fast, and flexible production lines for assembling complex electronic boards at a reasonable price.

Furthermore, many EMS companies provide assembly processes for combining printed circuit board assembly, together with cable harnesses assembly, box build or electro-mechanical assemblies along with the testing procedures. This provides the complete assembly services, where the OEM gets a complete offer and does not have to at all be involved in the production process at all.

The scope of services that electronic manufacturing services companies provide will vary one from another, depending on their strategy and capabilities. In summary, you can expect the following assembly services:

- PCB assembly (including. SMT Assembly, THT Assembly and Conformal Coating)

- Box Build (including Potting)

- Electromechanical assembly (including Cabinet Assembly)

- After-Sales Services (such as refurbishments, repairs, upgrades etc.)

Working with a partner that offers wide-scope electronics manufacturing services means that the OEM gets all required services under one roof and within a one-process flow, keeping every aspect of the entire process under control.

The EMS providers also offer assistance with a variety of associated services, in particular:

Engineering Support

Electronics manufacturing service providers retain professional technicians and engineers experienced in product management, production processes and testing. Thanks to this, the EMS can provide Customer’s product management support within the whole production life cycle. This includes BOM and revision management, component engineering, as well as ECO management and other associated capabilities, such as support with working with product certification entities, such as ETL, TUV or UL. Furthermore, the broad knowledge of the production process and material structure, allows a good electronics manufacturer to offer design for manufacturability (DfM) or design for test (DfT) services.

New Product Introduction

One of the most critical processes in electronic manufacturing is the New Product Introduction process, also known as NPI. A qualified EMS provider will conduct an in-depth evaluation of the new product before its implementation to the serial production. This will include a very complex study of the potential risks during the production (P-FMEA evaluation), all programs preparation, as well as trial production and material verification (eg. RLCD measurements). Such procedure also takes into account the design, build and preparation of all necessary product-specific tooling (eg. stencils, soldering frames)

Supply Chain Management and Procurement

Guided by the product specification and bill of materials (BOMs), the electronics manufacturing supplier conducts complete procurement and sourcing operations, where most importantly he finances the material on behalf of the OEM resulting in a positive cash flow for the Customer.

Professional electronic manufacturing services companies strive to optimize service costs through the most optimal supply chain management, which in most cases represent the circa 80% of the product value. As a result, good EMS partners place an enormous role in supporting OEMs in achieving their business goals.

Testing

An electronics manufacturing supplier, may perform functional tests with the use of equipment provided directly by the Customer, the EMS company can provide functional and ICT test development services, as well as related engineering support. Performing a functional test is a key process and ensures that only fully operational devices end up at the final customer.

Box Build Assembly Services

Box build assemblies are an all-in-one PCBA integrated with an electromechanical system, depending on the application. The demand for box build assembly services is rising with the expansion of fields like mechatronics and robotics, and their industrial applications. Box build assemblies are designed and developed for industrial equipment. Developing these systems requires expertise and meticulous attention to detail.

At Benchuang Electronics we offer Box build assembly services right from integrating simple PCBAs to designing and assembling complex box build assemblies for industrial setups. Benchuang Electronics offers kitting services for PCB assembly where we populate and assemble the PCBs with components received from the client. Every project is different, so, the board design as well as component quantity requirements differ too. Hence, as one of the reliable box build assembly manufacturers, we follow industry standards, never compromise on accuracy, and cater to specific requirements of our clients to offer them customized assembly.

Get started with Electronic Manufacturing Services

- Box build assembly

- Flex pcb assembly

- Rigid flex assembly

- SMT Assembly, BGA Assembly, Through hole Assembly, Mixed Assembly