You’ve likely heard the saying “you get what you pay for,” and while it might not be true for everything, the adage is definitely applicable to printed circuit boards. We know many businesses and organizations are in the market for cheap PCB manufacturing and assembly, but there’s a few important considerations you should know before placing your next order.

5 Main Factors That Affect PCB Cost

There’s a lot that affects the price of a printed circuit board. Here are the main points to keep in mind:

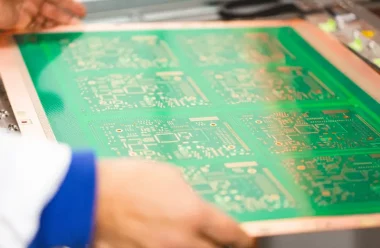

- Number of layers and PCB size

The greater the number of layers (and the bigger the board), the more expensive the project. - Order quantity

The price of the PCB will decrease if you order more boards. - Turnaround time

How quickly do you need your PCB? A quick turn fabrication (in as little as 24 hours) will typically result in a higher cost. - Material selection

Printed circuit boards are only as good as the materials they’re made from, which means the right high-quality materials will result in a PCB that not only works properly, but also lasts for the expected lifespan of the product. The cost of materials typically increases when the printed circuit board contains gold, blind or buried vias, or via filling. This is because of an increased number of processes needed for fabrication. Line and width spacing below 6 mils may also increase the cost. - Technology

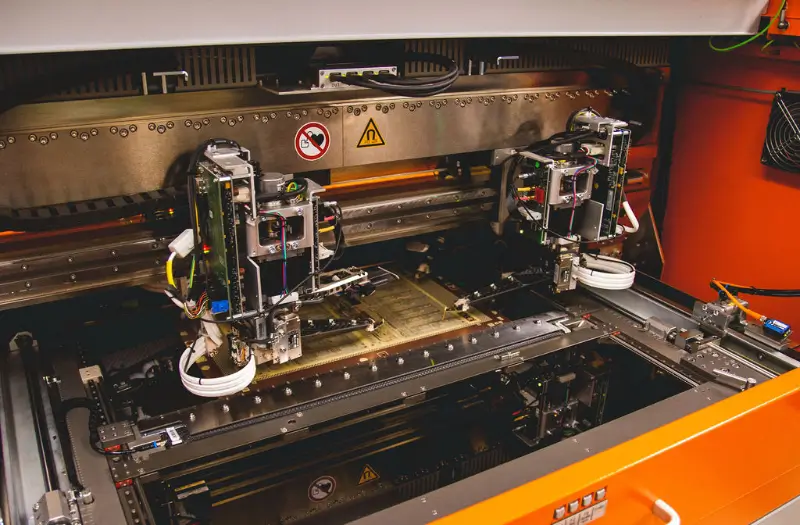

The kind of technology a company uses for PCB design, fabrication, and assembly — including for quick turn capabilities — will impact the price. Companies that use more advanced technology, which typically results in a better board, often feature higher prices.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)

![Determining PCB Via Size [w Guidelines] Determining PCB Via Size [w Guidelines]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Determining-PCB-Via-Size-w-Guidelines-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)

![PCB Material Types Explained [Your Guide] PCB Material Types Explained [Your Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/PCB-Material-Types-Explained-Your-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)