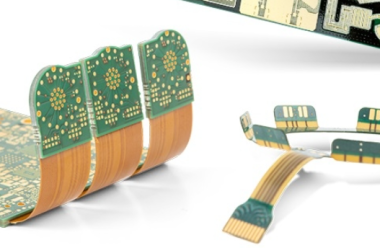

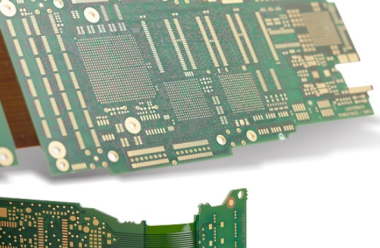

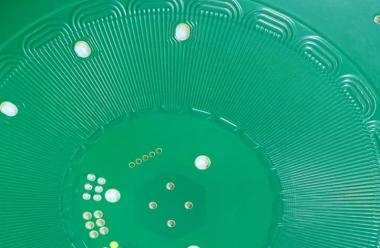

Flexible circuits are ideal for projects where it’s important to save weight and space and incorporate complex designs. There are three types of flexible circuits — flex, rigid-flex, and flex high density interconnect (HDI)— but what types of material do they require? In this guide, we cover how to select the right materials, plus popular stackups, copper types, and much more.

Selecting PCB Board Material

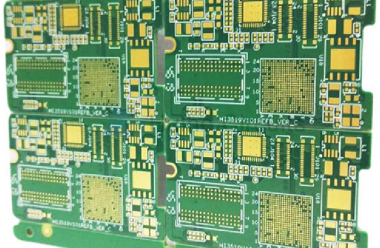

The material you select will depend on the type of flexible circuit and the number of layers in it. For example, a flex (or flexible) circuit might be as simple as one layer. A multilayer flex board will contain three or more copper conductive layers usually with plated through holes. Rigid-flex boards contain laminate materials that have higher temperature capabilities since they need to withstand at least three lamination cycles.

Certain projects may have Underwriters Laboratory (UL) requirements (now rebranded as UL Solutions), which the nonprofit organization explains here: “As a global safety science leader, UL Solutions helps companies to demonstrate safety, enhance sustainability, strengthen security, delivery quality, manage risk and achieve regulatory compliance.”

Other considerations that will factor into board material selection include the number of layers, the bend radius, and whether the project is a dynamic or flex-to-install application.

- Copper foil is one of the most commonly used materials because it is a highly conductive element used to make signal traces that conduct electricity.

- Dupont’s acrylic adhesive systems are commonly used in flex circuits, especially the FR series and the LF series. Though the LF series is used on Class 3 high-reliability projects, it is not a UL-approved product. The FR series, however, is UL-approved.

- An epoxy-based adhesive system provides better hole quality than an acrylic system; it also has a maximum continuous operating temperature of 150°C, as opposed to 105°C for acrylic.

- Almost 95% of projects that are built on base material for flex or rigid-flex circuits use adhesiveless materials. Dupont, Panasonic, ThinFlex all make adhesiveless products that are IPC 4204/11-certified.

- The polyimide base film is a type of lightweight material that can be very flexible and withstand high temperatures.

- Another popular choice is HT, which is an adhesiveless material that is an uncured polyimide that’s often used for coverlay applications. This material has low outgassing, high reliability, and high-temperature application.

- There are nine major surface finishes for printed circuit boards. Electroless Nickel Immersion Gold (ENIG) is the most popular option that’s used on approximately 80% of all boards. This finish provides a thin, gold, solderable layer that protects the copper traces with a nickel barrier between it and the copper. This is also a good lead-free option. Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) is another option.

Adhesive vs. Adhesiveless Attachments

Adhesive materials use either an acrylic or epoxy-based layer to connect the copper to the board.

An attachment could be anything from the lamination of multiple layers together to attaching stiffeners, including thermal-set adhesive systems.

The more adhesive that’s added to a project will increase the likelihood of having hole quality issues when it comes to drilling.

Pressure-sensitive adhesives are sometimes used to attach stiffeners. This is only recommended in thru-hole applications.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)