How to Choose High Density Interconnect PCB Materials: Key Criteria & Expert Insights

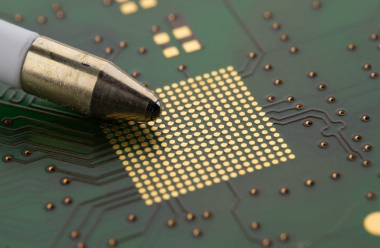

Selecting the right materials for high density interconnect (HDI) PCBs is the cornerstone of reliable performance, manufacturability, and cost-effectiveness. Whether designing HDI flexible pcb, HDI rigid flex pcb, rf pcb, or multilayer pcb, material choices directly impact microvia quality, signal integrity, thermal management, and compatibility with processes like sequential lamination. This guide, built on two decades of HDI manufacturing experience and alignment with IPC standards, breaks down the critical factors, material categories, and actionable selection frameworks to resolve common pain points in HDI design and production.

Learn more about How to Design HDI Microvia PCB

Key Considerations for HDI Materials

Laser Drillability

Laser drillability defines the ability to create precise microvias (≤0.15mm diameter) and blind vias—core features of HDI pcb and hdi circuit boards. Poor drillability leads to excessive dielectric smear, uneven hole walls, and reduced plating adhesion, all of which compromise reliability. Critical factors include:

- Dielectric hardness: Materials with Shore D hardness between 70–85 balance drillability and structural integrity; values above 85 increase tool wear and smear.

- Resin content: Resin-rich materials (resin content ≥50%) produce cleaner holes than fiber-dominant substrates, reducing post-drill deburring requirements.

- Glass transition temperature (Tg): Materials with Tg ≥140°C maintain dimensional stability during laser drilling, preventing hole wall distortion.

- Drill parameters: UV laser wavelengths (355nm) pair best with low-loss dielectrics for microvias down to 0.025mm, while CO₂ lasers work for larger blind vias in standard FR-4.

For HDI rigid flex pcb, polyimide-based materials require optimized laser power (10–20W) to avoid damaging flexible layers, with drill speed adjusted to 50,000–70,000 holes per minute for consistent results.

Thermal Stability

Thermal stability ensures HDI pcb performance under operating temperatures and manufacturing processes like soldering and sequential lamination. Failure to prioritize this leads to board warpage, delamination, and microvia cracking. Key metrics include:

- Tg (Glass Transition Temperature): Minimum Tg of 140°C for standard HDI; 170°C+ for high-temperature applications (e.g., automotive, industrial).

- Td (Decomposition Temperature): Minimum 300°C to withstand reflow soldering (260°C for 10 seconds, per IPC-6012 Class 3).

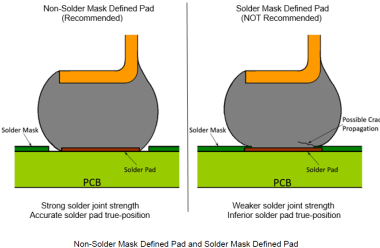

- CTE (Coefficient of Thermal Expansion): X/Y axis CTE ≤14 ppm/°C (0–100°C) to match component CTE, reducing thermal stress on microvias and solder joints.

- Z-axis CTE: ≤70 ppm/°C to prevent via barrel cracking during thermal cycling.

For rf pcb and high-speed HDI designs, materials with low CTE variation (≤5 ppm/°C across 0–150°C) maintain impedance consistency, critical for signal integrity at frequencies above 10GHz.

Signal Integrity

Signal integrity (SI) determines how well HDI pcb transmit high-speed signals without degradation—essential for rf pcb, 5G modules, and high-performance computing. Material properties directly influence SI through:

- Dielectric constant (Dk): Low and stable Dk (3.0–3.8) minimizes signal delay; variation ≤±0.05 across operating frequencies (1–40GHz) is mandatory for high-speed designs.

- Dissipation factor (Df): Low Df (≤0.005) reduces signal attenuation; values above 0.01 cause significant loss at frequencies >20GHz.

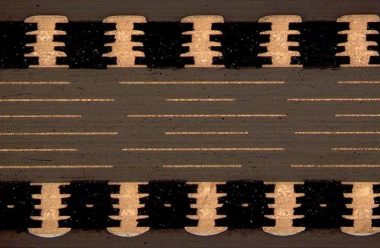

- Dielectric thickness uniformity: Variation ≤±0.005mm ensures consistent impedance (±5% tolerance, per IPC-2226) across the board.

- Copper surface roughness: Low-profile copper (Ra ≤0.8μm) reduces skin effect losses in high-frequency applications, outperforming standard copper (Ra 1.5–2.0μm).

For multilayer pcb with 8+ layers, choosing materials with matched Dk (±0.1) between signal layers prevents signal skew, a common issue in HDI designs with tight timing budgets.

Sequential Lamination Compatibility

Sequential lamination enables the creation of stacked microvias and complex layer structures in HDI pcb, making material compatibility non-negotiable. Incompatible materials cause delamination, resin flow, and misalignment. Key requirements include:

- Prepreg compatibility: Prepreg must match the core material’s Tg, resin content, and CTE to ensure uniform bonding.

- Resin flow: Controlled resin flow (20–30% during lamination) fills gaps between layers without covering microvias or traces.

- Bonding strength: Minimum peel strength of 1.5 N/mm (per IPC-6012) between laminated layers to withstand thermal and mechanical stress.

- Alignment stability: Materials must maintain dimensional stability (±0.005mm per layer) during lamination to ensure via registration.

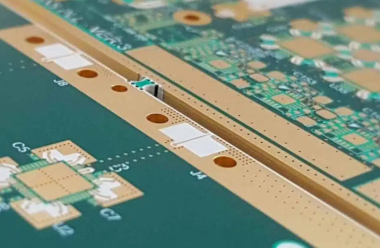

For HDI flexible pcb and HDI rigid flex pcb, flexible prepregs (e.g., polyimide-based) with low flow (≤10%) are used to preserve flexibility in bendable sections.

Commonly Used HDI Materials: Categories & Applications

HDI materials are categorized by performance, speed, and cost to align with specific application needs. Below is a breakdown of each category, including key materials, technical specs, and ideal use cases—designed to resolve cost-performance tradeoff dilemmas.

Standard/Low Cost HDI Materials

Standard/low cost materials balance basic HDI requirements with affordability, ideal for consumer electronics and non-critical applications. Key options include:

- FR-4 (Tg 140–150°C):

- Dk: 4.2–4.5 (1GHz), Df: 0.018–0.022 (1GHz)

- Laser drillability: Suitable for microvias ≥0.08mm; requires post-drill plasma deburring.

- Compatibility: Works with sequential lamination and subtractive etching.

- Applications: Entry-level HDI pcb, multilayer pcb for smartphones, IoT devices.

- Cost advantage: 30–50% lower cost than high-speed materials; high availability.

- Shengyi S1000:

- Dk: 4.3 (1GHz), Df: 0.019 (1GHz)

- Tg: 145°C, Td: 320°C

- Laser drillability: Microvias ≥0.08mm; good resin flow for sequential lamination.

- Applications: Low-cost HDI pcb, consumer electronics (tablets, wearables).

- FR-4 High Tg (Tg 170–180°C):

- Dk: 4.1–4.4 (1GHz), Df: 0.016–0.020 (1GHz)

- Thermal stability: Withstands 6+ reflow cycles (260°C); reduces warpage in 10+ layer boards.

- Applications: Mid-range HDI rigid flex pcb, automotive infotainment systems.

Medium Speed HDI Materials

Medium speed materials deliver improved signal integrity for data rates up to 10Gbps, suitable for industrial controls and mid-tier communication devices. Key options include:

- Isola FR408HR:

- Dk: 3.66 (1GHz), Df: 0.008 (1GHz)

- Laser drillability: Excellent for microvias ≥0.06mm; minimal smear.

- Sequential lamination: Resin flow optimized for stacked microvias.

- Applications: Medium-speed HDI pcb, multilayer pcb for Ethernet (10GBASE-T) devices.

- Shengyi S1130:

- Dk: 3.5–3.7 (1GHz), Df: 0.007–0.009 (1GHz)

- CTE: 12 ppm/°C (X/Y), 65 ppm/°C (Z); reduces thermal stress.

- Applications: HDI flexible pcb, portable electronics requiring moderate speed.

- Panasonic Megtron 4:

- Dk: 3.8 (1GHz), Df: 0.008 (1GHz)

- Tg: 170°C, Td: 360°C

- Laser drillability: Microvias ≥0.05mm; compatible with mSAP process.

- Applications: Mid-range high-speed HDI pcb, networking equipment.

- Nelco N4000-13:

- Dk: 3.6 (1GHz), Df: 0.007 (1GHz)

- Moisture absorption: <0.15% (24hrs @ 100°C)

- Applications: Industrial HDI rigid flex pcb, harsh-environment electronics.

High Speed/Low Loss HDI Materials

High speed/low loss materials support data rates up to 40Gbps, critical for high-performance computing and 5G sub-6GHz applications. Key options include:

- MEGTRON 8:

- Dk: 3.0 (1GHz), Df: 0.0025 (1GHz); stable Dk (±0.02) up to 40GHz.

- Laser drillability: Exceptional for microvias down to 0.04mm; no smear.

- Thermal stability: Tg 180°C, Td 380°C; suitable for sequential lamination.

- Advantages: 20% lower signal loss than MEGTRON 6; ideal for dense HDI pcb.

- Applications: High-speed multilayer pcb, 5G base station components, AI accelerators.

- Rogers 4350B:

- Dk: 3.48 (1GHz), Df: 0.0037 (1GHz)

- Copper compatibility: Works with low-profile copper for minimal skin effect loss.

- Applications: rf pcb, HDI rigid flex pcb for 5G mmWave modules.

- Isola I-Tera MT40:

- Dk: 3.2 (1GHz), Df: 0.0028 (1GHz)

- Tg: 185°C, Td: 390°C

- Laser drillability: Microvias down to 0.03mm; low Z-axis CTE (60 ppm/°C).

- Applications: 40Gbps HDI pcb, data center switches.

- Taiyo Yuden TLX-8:

- Dk: 3.1 (1GHz), Df: 0.0027 (1GHz)

- Signal loss: 0.15 dB/inch @ 28GHz (with low-profile copper)

- Applications: High-speed rf pcb, 5G small cells.

- Dupont Pyralux AP:

- Dk: 3.3 (1GHz), Df: 0.003 (1GHz)

- Flexible substrate: Polyimide core for HDI flexible pcb.

- Applications: High-speed flexible HDI pcb, foldable devices.

Very High Speed/RF HDI Materials

Very high speed/RF materials enable data rates >40Gbps and frequencies >20GHz, essential for aerospace, defense, and 5G mmWave applications. Key options include:

- MEGTRON 9:

- Dk: 2.9 (1GHz), Df: 0.0020 (1GHz); industry-low Df for ultra-high speed.

- Signal integrity: 15% lower insertion loss than MEGTRON 8 at 40GHz.

- Laser drillability: Supports microvias down to 0.025mm; ideal for ultra-dense HDI.

- Thermal stability: Tg 190°C, Td 400°C; withstands extreme operating conditions.

- Applications: Very high-speed HDI pcb, 5G mmWave rf pcb, satellite communication systems.

- Rogers RT/duroid 5880:

- Dk: 2.2 (1GHz), Df: 0.0009 (1GHz); best-in-class for RF performance.

- Moisture resistance: Low water absorption (<0.04%) for reliable outdoor use.

- Applications: HDI rf pcb, radar systems, high-frequency test equipment.

- Rogers 6002:

- Dk: 2.94 (1GHz), Df: 0.0012 (1GHz)

- Tg: 230°C, Td: 410°C

- Applications: Ultra-high-speed HDI pcb, aerospace communication systems.

- Isola Astra MT77:

- Dk: 2.8 (1GHz), Df: 0.0018 (1GHz)

- Signal loss: 0.12 dB/inch @ 40GHz

- Applications: 100Gbps HDI pcb, data center transceivers.

- Panasonic Megtron 10:

- Dk: 2.7 (1GHz), Df: 0.0015 (1GHz)

- Laser drillability: Microvias down to 0.02mm; ultra-low CTE (10 ppm/°C X/Y).

- Applications: Next-gen 5G mmWave HDI pcb, quantum computing hardware.

Material Comparison Table for HDI PCB

| Material Series | Model/Grade | Tg (°C) | Td (°C) | Dk (1GHz) | Df (1GHz) | Dk Stability (±@40GHz) | Min Microvia Diameter | X/Y CTE (ppm/°C) | Z CTE (ppm/°C) | Moisture Absorption (%) | Resin Content (%) | Copper Compatibility | Sequential Lamination | Max Data Rate | Max Frequency | Ideal Application | Cost Relative to FR-4 | Compliance Standards |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard FR-4 | Generic Std Tg | 140-150 | 310-330 | 4.2-4.5 | 0.018-0.022 | ±0.2 | 0.08mm (3.2mil) | 14-16 | 75-85 | 0.2-0.3 | 45-50 | Standard Electrolytic (Ra 1.5-2.0μm) | Yes | 2Gbps | 1GHz | Entry-level HDI pcb, IoT devices | 1x | IPC-4101, UL 94V-0 |

| Standard FR-4 | High Tg (170-180°C) | 170-180 | 340-360 | 4.1-4.4 | 0.016-0.020 | ±0.18 | 0.08mm (3.2mil) | 13-15 | 70-80 | 0.2 | 46-51 | Standard/Low-profile (Ra ≤1.0μm) | Yes (controlled flow) | 3Gbps | 2GHz | Automotive infotainment | 1.2x | IPC-4101/21, UL 94V-0 |

| Shengyi | S1000 | 145 | 320 | 4.3 | 0.019 | ±0.2 | 0.08mm (3.2mil) | 15 | 80 | 0.25 | 47-52 | Standard Electrolytic | Yes | 2Gbps | 1GHz | Low-cost HDI flexible pcb | 1.1x | IPC-4101, UL 94V-0 |

| Shengyi | S1130 | 175 | 365 | 3.5-3.7 | 0.007-0.009 | ±0.08 | 0.06mm (2.4mil) | 12 | 65 | 0.15 | 50-55 | Low-profile (Ra ≤0.8μm) | Yes | 10Gbps | 10GHz | HDI flexible pcb, high-speed devices | 1.7x | IPC-4101, UL 94V-0 |

| Isola | FR408HR | 180 | 370 | 3.66 | 0.008 | ±0.07 | 0.06mm (2.4mil) | 12 | 65 | 0.18 | 51-56 | Low-profile (Ra ≤0.8μm) | Yes (optimized flow) | 10Gbps | 10GHz | 10GBASE-T Ethernet | 1.8x | IPC-4101, UL 94V-0 |

| Isola | I-Tera MT40 | 185 | 390 | 3.2 | 0.0028 | ±0.03 | 0.03mm (1.2mil) | 11 | 60 | 0.1 | 53-58 | Ultra-low-profile (Ra ≤0.5μm) | Yes (precision lamination) | 40Gbps | 40GHz | Data center switches | 3.8x | IPC-4101/22, UL 94V-0 |

| Isola | Astra MT77 | 195 | 400 | 2.8 | 0.0018 | ±0.02 | 0.025mm (1mil) | 10 | 55 | 0.08 | 54-59 | Ultra-low-profile (Ra ≤0.5μm) | Yes (ultra-precise flow) | 100Gbps | 60GHz | 5G mmWave rf pcb | 5.5x | IPC-4101/22, MIL-P-13949G |

| Panasonic Megtron | Megtron 4 | 170 | 360 | 3.8 | 0.008 | ±0.09 | 0.05mm (2mil) | 13 | 70 | 0.15 | 49-54 | Low-profile (Ra ≤0.8μm) | Yes (mSAP compatible) | 10Gbps | 12GHz | Networking equipment | 2x | IPC-4101, UL 94V-0 |

| Panasonic Megtron | Megtron 8 | 180 | 380 | 3 | 0.0025 | ±0.02 | 0.04mm (1.6mil) | 11 | 60 | 0.1 | 52-57 | Ultra-low-profile (Ra ≤0.5μm) | Yes (stacked microvia) | 40Gbps | 40GHz | 5G base stations, AI accelerators | 3.5x | IPC-4101/22, UL 94V-0 |

| Panasonic Megtron | Megtron 9 | 190 | 400 | 2.9 | 0.002 | ±0.01 | 0.025mm (1mil) | 10 | 55 | 0.09 | 53-58 | Ultra-low-profile (Ra ≤0.3μm) | Yes (any-layer lamination) | 100Gbps | 60GHz | Satellite communication | 5x | IPC-4101/22, MIL-P-13949G |

| Panasonic Megtron | Megtron 10 | 200 | 410 | 2.7 | 0.0015 | ±0.01 | 0.02mm (0.8mil) | 10 | 50 | 0.07 | 55-60 | Ultra-low-profile (Ra ≤0.3μm) | Yes (extreme density) | 200Gbps | 100GHz | Quantum computing | 8x | IPC-4101/22, MIL-P-13949G |

| Nelco | N4000-13 | 180 | 380 | 3.6 | 0.007 | ±0.08 | 0.05mm (2mil) | 12 | 68 | 0.12 | 48-53 | Low-profile (Ra ≤0.8μm) | Yes | 15Gbps | 15GHz | Industrial HDI rigid flex pcb | 2.2x | IPC-4101, UL 94V-0 |

| Rogers | 4350B | 150 | 370 | 3.48 | 0.0037 | ±0.05 | 0.05mm (2mil) | 13 | 65 | 0.1 | 51-56 | Ultra-low-profile (Ra ≤0.5μm) | Yes (RF-optimized) | 40Gbps | 30GHz | 5G mmWave rf pcb | 4x | IPC-4101, UL 94V-0 |

| Rogers | RT/duroid 5880 | 260 | 420 | 2.2 | 0.0009 | ±0.02 | 0.05mm (2mil) | 11 | 58 | 0.04 | 58-63 | Ultra-low-profile (Ra ≤0.3μm) | Yes (high-temperature) | 100Gbps | 100GHz | Radar systems | 8x | MIL-P-13949G, IPC-4101 |

| Rogers | 6002 | 230 | 410 | 2.94 | 0.0012 | ±0.03 | 0.04mm (1.6mil) | 12 | 62 | 0.06 | 55-60 | Ultra-low-profile (Ra ≤0.5μm) | Yes (aerospace-grade) | 100Gbps | 80GHz | Aerospace communication | 6x | MIL-P-13949G, IPC-4101 |

| Taiyo Yuden | TLX-8 | 180 | 385 | 3.1 | 0.0027 | ±0.04 | 0.04mm (1.6mil) | 11 | 61 | 0.11 | 52-57 | Low-profile (Ra ≤0.8μm) | Yes | 40Gbps | 28GHz | 5G small cells | 3.2x | IPC-4101, UL 94V-0 |

| Dupont | Pyralux AP | 250 | 430 | 3.3 | 0.003 | ±0.05 | 0.05mm (2mil) | 14 | 68 | 0.08 | 53-58 | Low-profile (Ra ≤0.8μm) | Yes (flexible lamination) | 40Gbps | 30GHz | High-speed HDI flexible pcb | 4.5x | IPC-4101, UL 94V-0 |

Recommendation Framework for HDI Material Selection

Step-by-Step Selection Process

- Define Performance Requirements:

- Data rate: <2Gbps (standard), 2–10Gbps (medium), 10–40Gbps (high), >40Gbps (very high).

- Frequency: <1GHz (standard), 1–20GHz (high), >20GHz (RF).

- Operating temperature: -40°C to 85°C (consumer), -55°C to 125°C (industrial/aerospace).

- Assess Manufacturing Constraints:

- Microvia size: ≤0.04mm (requires MEGTRON 8/9 or Rogers), 0.06–0.08mm (FR408HR/S1130), ≥0.08mm (standard FR-4).

- Layer count: 4–8 layers (standard FR-4), 8–16 layers (high Tg FR-4/FR408HR), 16+ layers (MEGTRON 8/9).

- Process type: Sequential lamination (prioritize materials with controlled resin flow).

- Align with Application Type:

- Consumer electronics: Standard FR-4 or FR408HR for cost efficiency.

- 5G sub-6GHz: MEGTRON 8 or Rogers 4350B for balanced speed and cost.

- 5G mmWave/RF: MEGTRON 9 or Rogers RT/duroid 5880 for minimal signal loss.

- Automotive: High Tg FR-4 or FR408HR for thermal stability.

- HDI flexible pcb/HDI rigid flex pcb: Polyimide-based materials (e.g., Shengyi S1130) for flexibility.

- Balance Cost & Performance:

- Cost-sensitive projects: Standard FR-4 (30–50% cost savings vs. high-speed materials).

- Performance-critical projects: MEGTRON 8/9 (20–30% better signal integrity vs. mid-tier materials).

- Mid-range projects: Isola FR408HR (balances cost, speed, and manufacturability).

Application-Specific Recommendations

- Smartphones/Tablets: Standard FR-4 (entry-level) or FR408HR (premium) for HDI pcb with microvias ≥0.08mm. Prioritize cost and availability.

- 5G Base Stations: MEGTRON 8 for sub-6GHz applications; MEGTRON 9 for mmWave rf pcb. Ensures signal integrity at 28GHz+.

- Automotive ADAS: High Tg FR-4 or FR408HR for HDI rigid flex pcb. Withstands under-hood temperatures and thermal cycling.

- Medical Devices: Rogers 4350B (biocompatible options) for HDI pcb in imaging equipment. Low signal loss and high reliability.

- Aerospace/Defense: MEGTRON 9 or Rogers RT/duroid 5880 for very high-speed HDI pcb. Resists extreme temperatures and radiation.

Critical Factors for Specialized HDI Applications

HDI Flexible PCB & HDI Rigid Flex PCB

Flexible HDI designs require materials that combine flexibility with HDI capabilities:

- Substrates: Polyimide (PI) with Tg 250°C+ for flexibility and thermal stability.

- Prepregs: Flexible PI prepregs with low resin flow (≤10%) to preserve bendability.

- Copper: Thin copper (12μm–18μm) for fine trace etching; rolled copper for better flexibility than electrolytic copper.

- Limitations: Microvia diameters ≥0.05mm (due to flexible material properties); avoid high-loss materials for RF flexible designs.

RF HDI PCB

RF HDI requires materials that minimize signal loss and maintain impedance consistency:

- Low Dk/Df: Dk ≤3.5, Df ≤0.005 (1GHz) to reduce attenuation.

- Low water absorption: <0.1% to prevent Dk variation in humid environments.

- Copper surface: Low-profile copper (Ra ≤0.8μm) to reduce skin effect losses.

- MEGTRON 9 and Rogers RT/duroid 5880 are industry standards for RF HDI, supporting frequencies up to 100GHz.

Multilayer HDI PCB (16+ Layers)

High-layer-count HDI requires materials with exceptional dimensional stability:

- Tg ≥180°C (MEGTRON 8/9) to prevent warpage during sequential lamination.

- CTE ≤12 ppm/°C (X/Y) to align layers and avoid microvia misalignment.

- Controlled resin flow (20–25%) to fill gaps without shorting traces.

- Material matching: Ensure core and prepreg have identical Dk/CTE to maintain signal integrity across layers.

Compliance & Standards for HDI Materials

Adherence to industry standards ensures HDI material quality and compatibility with manufacturing processes. Key standards include:

- IPC-4101: Defines specifications for base materials (cores, prepregs) used in HDI pcb. Requires materials to meet minimum Tg, Td, and CTE requirements.

- IPC-6012: Establishes performance criteria for HDI circuit boards, including material-related requirements like peel strength and dielectric integrity.

- IPC-2226: Provides design guidelines for HDI pcb, including material selection based on microvia size and signal speed.

- UL 94: Fire safety standard; HDI materials for consumer and industrial applications must meet UL 94V-0 rating.

For aerospace and defense applications, materials must comply with MIL-P-13949G, which specifies rigorous quality and performance requirements for PCB substrates.

Best Practices for HDI Material Implementation

Material Handling & Storage

- Store materials in a controlled environment (20–25°C, 40–60% humidity) to prevent moisture absorption.

- Bake prepregs and cores (120°C for 2–4 hours) before lamination to remove moisture, which causes delamination.

- Use materials within their shelf life (typically 6–12 months from manufacture) to avoid resin degradation.

Compatibility Testing

- Conduct lamination trials to verify resin flow and bonding strength before full production.

- Perform laser drillability tests to optimize drill parameters (power, speed) for the selected material.

- Test signal integrity (insertion loss, crosstalk) with TDR/TDT equipment to confirm material performance at target frequencies.

Collaboration with Material Suppliers

- Engage suppliers early to confirm material availability, especially for specialized options like MEGTRON 9.

- Request material samples for testing before finalizing selection.

- Work with suppliers to resolve issues like inconsistent Dk or poor drillability, leveraging their technical expertise.

FAQ: Common HDI Material Selection Questions

What Is the Difference Between PCB and PCA?

PCB (Printed Circuit Board) refers to the bare board, consisting of substrates, copper traces, and vias—material selection directly impacts PCB performance. PCA (Printed Circuit Assembly) is the PCB with components (resistors, ICs) mounted; HDI material choice influences component compatibility (e.g., solderability, thermal management).

When Should I Choose MEGTRON 8 Over MEGTRON 9?

Choose MEGTRON 8 for high-speed applications (10–40Gbps) where cost is a consideration—it offers 30–40% lower cost than MEGTRON 9 while delivering excellent signal integrity. Opt for MEGTRON 9 only for very high-speed (≥40Gbps) or RF (≥28GHz) applications where minimal signal loss is critical.

Can Standard FR-4 Be Used for HDI PCB with Microvias?

Yes, but only for microvias ≥0.08mm. Standard FR-4 has higher Dk/Df than high-speed materials, limiting its use to low-speed (≤2Gbps) applications. It also requires more aggressive deburring after laser drilling to remove dielectric smear.

How Does Material Selection Impact HDI Manufacturing Lead Time?

Specialized materials like MEGTRON 9 or Rogers RT/duroid 5880 have longer lead times (4–6 weeks) than standard FR-4 (1–2 weeks). Early material selection and pre-ordering reduce production delays, especially for high-volume HDI pcb projects.

What Materials Are Best for HDI Rigid Flex PCB?

Polyimide-based substrates (e.g., Shengyi S1130) paired with flexible PI prepregs are ideal. They combine flexibility (for bendable sections) with HDI capabilities (microvias, sequential lamination) and maintain stability under thermal cycling.

Conclusion

Choosing the right materials for HDI pcb is a critical decision that impacts performance, manufacturability, and cost. By prioritizing factors like laser drillability, thermal stability, and signal integrity, and aligning material selection with application requirements, designers can create reliable HDI circuit boards for rigid flex pcb, rf pcb, and multilayer pcb. Materials like MEGTRON 8 and MEGTRON 9 set the standard for high-speed and RF applications, while standard FR-4 and FR408HR offer cost-effective solutions for consumer electronics. Adherence to IPC standards, collaboration with suppliers, and rigorous testing ensure material compatibility and performance, unlocking the full potential of high density interconnect technology. As HDI designs continue to evolve toward smaller microvias and higher speeds, material innovation and strategic selection will remain key to success in next-gen electronic applications.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)