- High frequency low loss PCB material

- Low loss high speed PCB materials

- R-5775, R-5785, R-5795, TU-872 SLK , TU-872 SLK SP, TU 933+, I-Tera MT40, Astra MT77, Tachyon 100G material

- EM-888, EM-888(S), EM-888(K), EM-526, EM-528, EM-528K, IT-968, IT-968 SE, IT-988G, IT-988G SE material

- PCB Sample Prototype, Flex & Rigid-Flex PCB, HDI Blind and Buried Microvias, High Frequency Low Loss PCB Material, Quick Turn PCB Manufacturer

High-Quality PCB Prototype Service & Quick Turn Prototype PCB Manufacturing

Quick Turn PCB Prototype Manufacturing & Fast Turn Prototype PCB Production

High-Precision Prototype PCB Production for Custom Printed Circuit Board Prototype

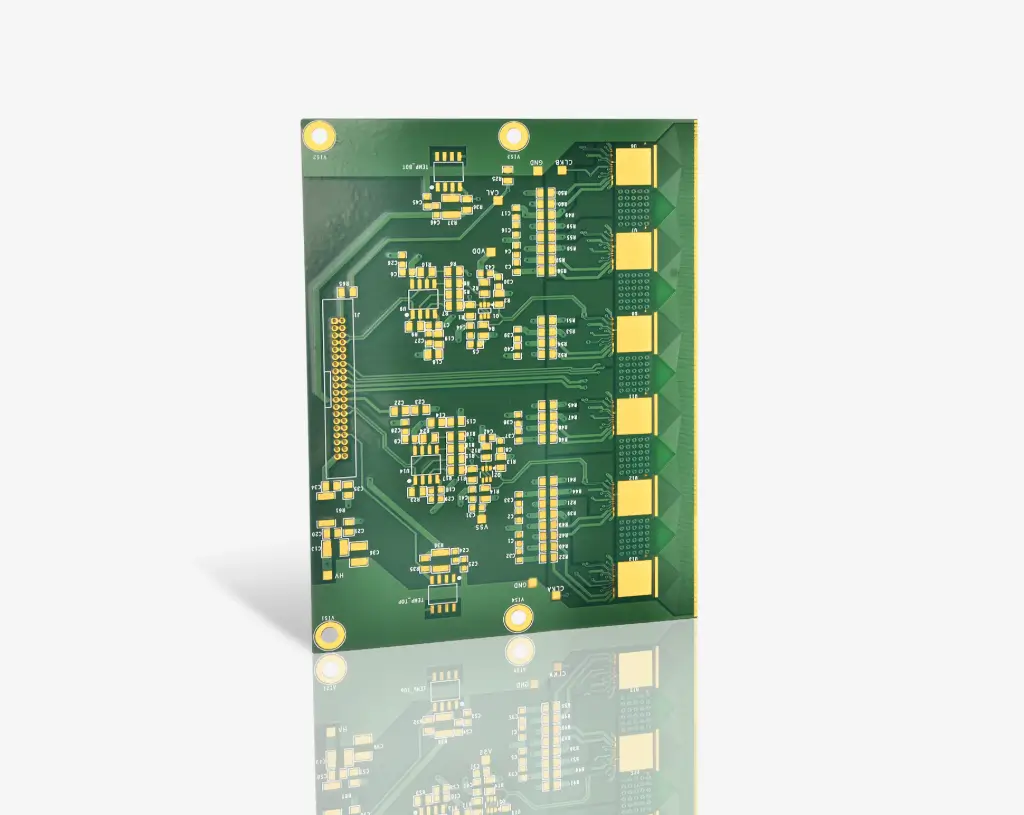

As a trusted proto PCB manufacturer, we specialize in high-precision printed circuit board prototype production tailored to diverse electronic project needs. Our prototype PCB manufacturing supports 2-layer to 16-layer board designs, with trace width/spacing as tight as 3mil/3mil (0.075mm/0.075mm) and minimum via diameter of 0.1mm—meeting IPC-6012 Class 2 standards for prototype reliability. We use advanced laser direct imaging (LDI) technology to ensure pattern accuracy within ±0.02mm, critical for high-density custom printed circuit board prototype projects like IoT sensor modules and industrial control units. Every batch undergoes 100% automated optical inspection (AOI) to catch trace defects, ensuring consistent quality across small-batch prototype runs (1-50 pcs) and pre-production batches (50-500 pcs).

Quick turn PCB fabrication and PCB assembly services are the foundation of our business. Our highly experienced manufacturing team is ready and willing to do whatever it takes to serve your New Product Introduction (NPI), PCB prototyping, breadboarding, modeling, and engineering needs.

Benchuang Electronics is proud to offer our quick turn PCB services to all customers, including full certification for defense products.

Quick Turn PCB Prototype Manufacturing with 24H Fast Turn PCB Lead Time

Our quick turn PCB prototype service stands out for ultra-fast lead times, with 24-hour turnaround available for standard 2-layer prototype PCB boards (FR-4 substrate, 1.6mm thickness, 1oz copper). For more complex designs—such as 4-layer SMD prototype boards or high-Tg (≥170℃) FR-4 prototypes—we guarantee 48-72 hour fast turn delivery, outpacing industry average lead times by 30%. This rapid response is enabled by our in-house production line optimization: 24/7 operational laser drilling machines, pre-stocked core materials (FR-4, aluminum, Rogers), and dedicated prototype engineering teams. We prioritize quick turn printed circuit boards for time-sensitive R&D projects, helping clients accelerate product development cycles and gain market first-mover advantages.

Cost-Saving Prototype PCB Manufacturing from Cheapest PCB Manufacturer

As a cost-effective PCB prototype manufacturer, we balance low costs with uncompromised quality through optimized supply chains and production efficiency. Our budget-friendly printed circuit board prototype solutions start at $29 for 5pcs of 2-layer PCB prototype boards (100x100mm), with volume discounts for pre-production batches (≥100 pcs) that reduce unit costs by up to 40%. We avoid hidden fees—quotations include lamination, drilling, copper plating, and basic AOI testing—making us the cheapest PCB manufacturer for small-batch prototype needs without sacrificing technical capabilities. For cost-sensitive projects like student prototypes or startup R&D, we offer economical PCB prototype solutions with optional cost-cutting adjustments (e.g., standard tolerance, reduced testing scope) while maintaining core functionality.

PCB Prototype and Assembly | Prototype PCB Assembly & Prototype Circuit Board Assembly

Reliable Prototype PCB Assembly for Prototype Circuit Board Assembly Projects

Our prototype PCB assembly service delivers reliable, production-ready assembly for prototype circuit board projects across industries. We support both through-hole and surface mount (SMT) assembly, with component placement accuracy of ±0.1mm for SMT parts (down to 0402 package size). Our assembly process follows IPC-A-610 Class 2 standards, including solder paste inspection (SPI) and automated optical inspection (AOI) post-assembly to ensure solder joint quality. For high-reliability projects—such as medical device prototypes or automotive electronic modules—we offer X-ray inspection for hidden solder joints (e.g., BGA packages) and conformal coating (Acrylic, Parylene) to protect against moisture and dust. We handle small-batch prototype assembly (1-100 units) with quick turnaround (3-5 days) and provide detailed assembly reports for regulatory compliance.

SMT Prototype Board & SMD Prototype Board Assembly for Surface Mount Prototype Board

We specialize in SMT prototype board and SMD prototype board assembly, catering to the growing demand for miniaturized surface mount prototype board designs. Our SMT assembly line supports high-speed placement of 0201 chip components, QFN packages, and fine-pitch BGAs (0.4mm pitch), with a maximum component density of 1200 components per square inch. For surface mount prototype board projects, we offer full turnkey assembly—sourcing components from authorized distributors (Digi-Key, Mouser) to ensure authenticity, or accommodating customer-supplied parts. We optimize solder profiles for different substrate materials (FR-4, polyimide for flexible prototypes) to prevent thermal damage, and conduct functional testing (ICT, FCT) to validate assembly performance for applications like wearable devices and 5G modules.

One-Stop PCB Prototype and Assembly Service for All Prototype Needs

Our one-stop PCB prototype and assembly service streamlines the prototype development process, eliminating the hassle of coordinating separate manufacturers for PCB fabrication and assembly. From design review to final functional testing, we handle every step: DFM (Design for Manufacturability) analysis to optimize PCB layout for assembly, prototype PCB manufacturing, component sourcing, assembly, and testing. This integrated approach reduces project lead times by 25% compared to split services and minimizes communication errors. We cater to diverse prototype needs—from simple proto PCB boards for hobby projects to complex prototype printed circuit board assembly for industrial automation.

Custom PCB Prototype Board & Proto PCB Boards for SMT/SMD Prototype Board

Durable PCB Prototype Board & Prototype Board PCB for Electronic Projects

Our durable PCB prototype board and prototype board PCB solutions are engineered for long-term reliability in electronic projects. We use high-quality FR-4 substrates (FR-406, FR-408) with 1oz-4oz copper foil, offering excellent mechanical strength and electrical conductivity. For harsh environment applications (temperature range: -40℃~125℃), we provide high-Tg FR-4 (Tg≥170℃) or aluminum-based prototype board PCB to enhance heat dissipation. Our PCB prototype boards feature ENIG (Electroless Nickel Immersion Gold) surface finish as standard, ensuring superior solderability and corrosion resistance (≥1000 hours salt spray test). For flexible electronic projects, we offer polyimide-based proto PCB boards with 100,000+ bending cycle durability, ideal for wearable sensors and foldable device prototypes.

High-Quality Proto PCB & PCB Proto Board for Quick Turn PCB Prototyping

Our high-quality proto PCB and PCB proto board solutions are optimized for quick turn PCB prototyping without compromising performance. We manufacture proto PCB boards with strict quality control: dielectric strength ≥20kV/mm, insulation resistance ≥10^12 Ω, and thermal conductivity of 0.35 W/m·K (FR-4). For quick turn applications, we pre-stock standard PCB proto board sizes (50x50mm, 100x100mm, 150x150mm) to reduce setup time, while supporting custom sizes up to 600x1200mm for larger prototypes. Our proto PCB boards undergo rigorous testing—including thermal shock testing (-55℃~125℃, 100 cycles) and humidity testing (85℃/85% RH, 500 hours)—to ensure reliability in quick-turn prototyping scenarios like trade show demos and investor presentations.

Custom Proto PCB Boards for Customized PCB Prototype Board Requirements

We offer custom proto PCB boards tailored to unique PCB prototype board requirements, accommodating non-standard sizes, shapes, and materials. Our custom capabilities include: irregular board shapes (cutouts, rounded edges) for space-constrained enclosures, mixed-substrate designs (FR-4 + polyimide for rigid-flex prototypes), and specialized surface finishes (OSP, HASL, immersion silver) for specific applications. For SMT/SMD prototype board projects, we customize solder mask openings (minimum 0.15mm) and silkscreen markings to match component layouts. We support custom layer stacks (e.g., 3-layer, 5-layer asymmetric designs) for high-performance prototypes like power supplies and RF modules. Our DFM team reviews all custom designs free of charge, ensuring manufacturability and optimizing for cost and lead time.

Cost-Effective PCB Prototype | Cheapest PCB Manufacturer for Printed Circuit Board Prototype

Budget-Friendly Printed Circuit Board Prototype from Top Prototype PCB Board Manufacturer

As a top prototype PCB board manufacturer, we offer budget-friendly printed circuit board prototype solutions that balance cost and quality. Our economies of scale—with 50,000+ prototype units produced monthly—allow us to pass savings to clients while maintaining strict quality standards. We offer tiered pricing for printed circuit board prototypes: $29 for 5pcs (2-layer, 100x100mm), $49 for 10pcs, and $89 for 50pcs, with no minimum order quantity. For budget-sensitive projects, we provide optional cost-saving measures: standard tolerance (±0.1mm for traces), OSP surface finish instead of ENIG, and reduced testing scope (visual inspection only). Despite being a cost-effective option, we never compromise on core materials—all prototypes use RoHS-compliant substrates and copper foil to ensure global market access.

Reliable Proto PCB Manufacturer & Prototype Printed Circuit Board Manufacturers

As a reliable proto PCB manufacturer and one of the leading prototype printed circuit board manufacturers, we prioritize transparency and quality. Our manufacturing facilities are ISO 9001:2015 certified, with strict quality management systems covering raw material incoming inspection, in-process testing, and final outgoing inspection. We source substrates from top suppliers (Isola, Rogers) and copper foil from certified mills, with full traceability for every batch (material certificates available upon request). Our prototype printed circuit board manufacturing process adheres to IPC-6013 standards, ensuring consistent performance across batches. We maintain a 99.8% on-time delivery rate and a 0.5% defect rate—well below industry averages—making us a trusted partner for global clients in aerospace, medical, and consumer electronics.

Cost-Effective PC Board Prototyping for Economical PCB Prototype Solutions

Our cost-effective PC board prototyping services deliver economical PCB prototype solutions for startups, educational institutions, and small businesses. We optimize PC board prototyping processes to reduce waste: using panelization to maximize substrate utilization (reducing material waste by 15%) and automating repetitive tasks (drilling, imaging) to lower labor costs. For economical PCB prototype solutions, we offer shared panel services—combining multiple clients’ small prototype designs on a single panel—to reduce setup costs. We also provide free DFM analysis to identify cost-saving opportunities (e.g., reducing layer count, optimizing trace width) without impacting functionality. Our goal is to make high-quality PC board prototyping accessible to all, regardless of project budget.

Quick Turn PCB Boards & Quick Turn Printed Circuit Boards for Fast Prototype Delivery

Fast-Track Quick Turn PCB Boards for Urgent Prototype Needs

Our fast-track quick turn PCB boards are designed for urgent prototype needs, with 24-hour delivery for standard 2-layer FR-4 boards (up to 100x100mm). We prioritize urgent orders with a dedicated production line, skipping non-essential processes (e.g., optional silkscreen) while maintaining core quality checks (AOI, continuity testing). For quick turn printed circuit boards requiring custom finishes (ENIG) or higher layer counts (4-layer), we offer 48-hour delivery, supported by our 24/7 production team. We use expedited shipping (DHL, FedEx) for fast prototype delivery, ensuring global clients receive their prototypes in 2-3 days (North America, Europe) or 3-5 days (Asia, Australia).

Quality-Guaranteed Quick Turn Printed Circuit Boards

Unlike many quick turn manufacturers that sacrifice quality for speed, our quick turn printed circuit boards maintain the same high standards as standard production. We use the same advanced equipment (LDI, laser drilling) for quick turn orders, ensuring trace accuracy and via quality. Every quick turn PCB board undergoes 100% continuity testing to check for open/short circuits, and we provide a 100% satisfaction guarantee—reworking or remanufacturing free of charge if defects are found. Our quality-focused approach makes us the preferred choice for urgent prototype projects that demand reliability, such as medical device clinical trials and automotive prototype testing.

Scalable Quick Turn PCB Solutions for Prototype to Production

Our quick turn PCB solutions are scalable, supporting clients from prototype to mass production. For initial R&D, we offer quick turn prototype boards (1-50 pcs) with fast delivery; as projects move to pre-production (50-500 pcs), we maintain quick lead times while optimizing for cost; for mass production (≥1000 pcs), we scale up production capacity while retaining the same quality standards. This scalability eliminates the need to switch manufacturers mid-project, reducing risk and ensuring design consistency. We provide volume discounts for scaled-up orders, with unit costs decreasing by up to 50% when moving from prototype to 10,000-unit production runs.

Professional PCB Prototype Service & Circuit Board Prototyping Service

Expert DFM Review for PCB Prototype Service

Our professional PCB prototype service includes free expert DFM (Design for Manufacturability) review to optimize circuit board prototyping designs. Our engineers—with 15+ years of prototype experience—analyze designs for potential issues: trace width/spacing violations, via placement, component clearance, and solder mask coverage. We provide detailed DFM reports with actionable recommendations (e.g., increasing trace width for high-current paths, relocating vias away from board edges) to reduce prototype iterations by 30%. This service is critical for first-time prototype designers and complex projects, ensuring designs are production-ready and avoiding costly rework.

Comprehensive Testing for Circuit Board Prototyping Service

Our circuit board prototyping service includes comprehensive testing to validate prototype performance. We offer a range of testing options: continuity testing (standard), AOI (automated optical inspection), X-ray inspection (for hidden solder joints), functional testing (FCT), and environmental testing (temperature, humidity, vibration). For high-reliability applications (aerospace, medical), we provide full qualification testing per MIL-STD-883 or IPC standards. We generate detailed test reports for each prototype batch, documenting performance metrics and ensuring compliance with project specifications. This testing rigor ensures prototypes accurately represent production units, reducing the risk of design flaws in final products.

Quick Turn PCB Capabilities

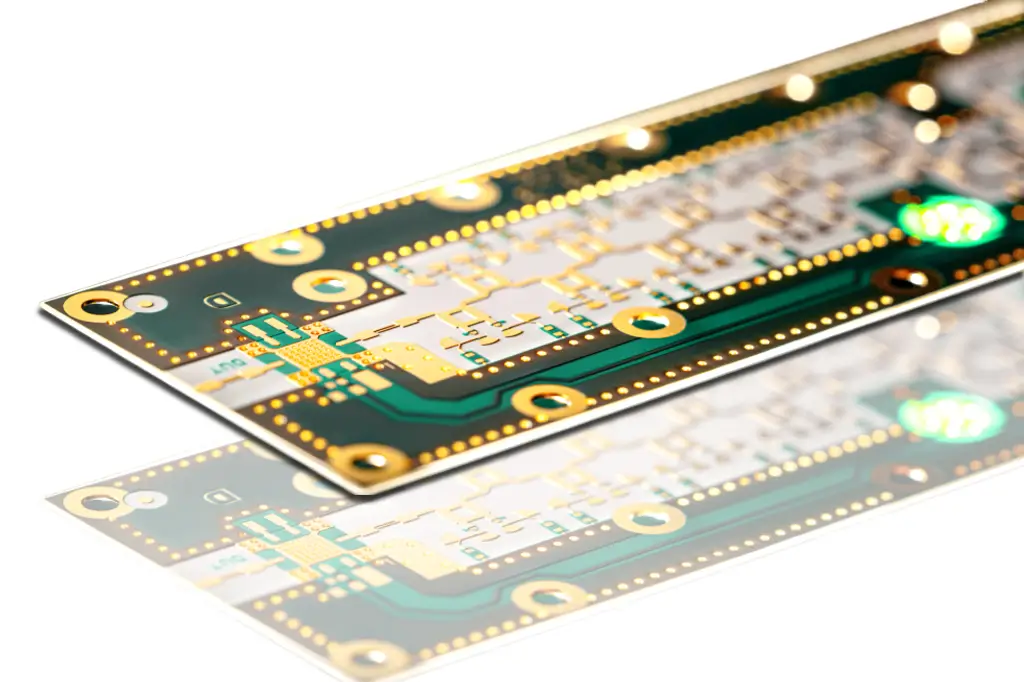

- HDI PCB

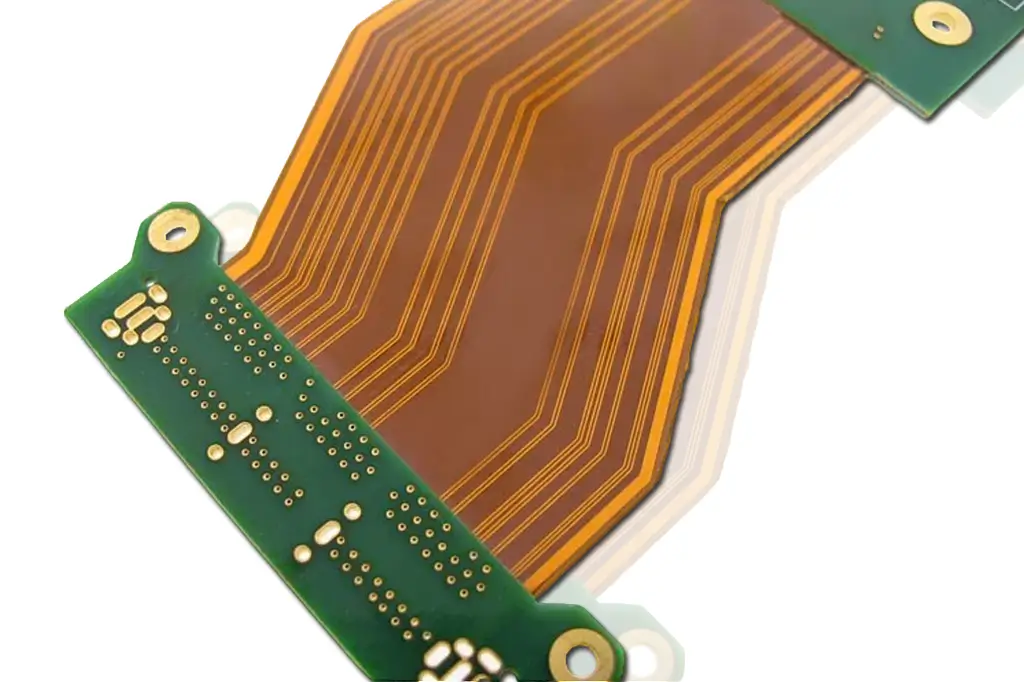

- Flexible Circuits

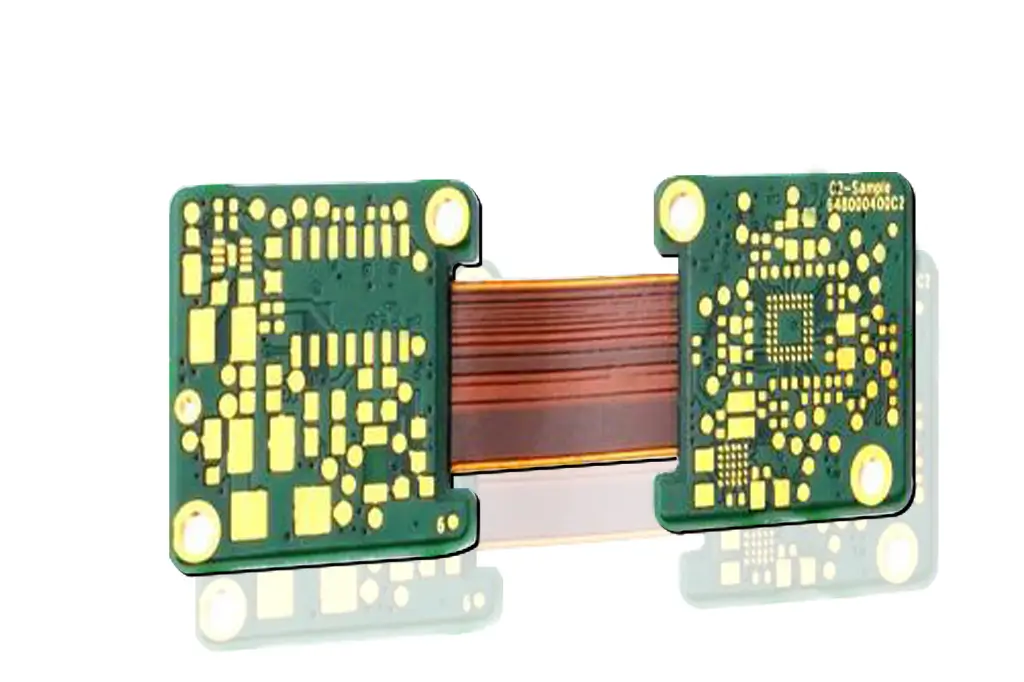

- Rigid flex PCB

- RF Microwave PCB

- High Frequency PCB

- Panasonic Megtron 6 PCB, Megtron 7, Megtron 8 PCB

- ROGERS RO3003, RO3010, RO4350, RO4850 PCB

- ISOLA 370HR, 408HR, I-Speed, I-Tera MT40, Astra MT77, Tachyon 100G PCB

- EMC EMC-285, EMC-370D, EMC-370Z, EMC-390, EMC-888, EMC-888S, EMC-888K, EMC-526,EMC-528, EMC-528K, EMC-890, EMC-890K, EMC-891, EMC-891K PCB

- TUC TUC-872LK, TUC-872SLK, TUC-872SLK SP, TUC-883, TUC-933, TUC-943 SN PCB

- Blind vias, buried vias, and other microvia techniques

- Laser direct imaging, fine lines, and via-in-pad technology

- Down to 1.5-mil trace space, 2-mil holes

Quick Turn PCB Tips

Every quick-turn PCB request is different in terms of technology, delivery requirements, and volume of parts needed. If you need a small quantity of 2-layer PCBs there are many Internet-based companies that can get you these parts very quickly and very inexpensively. However, here at Benchuang Electronics, we focus on more complex PCBs that require 100% absolute quality and consistency throughout the entire life of the development and into production. Truly understanding the technology that we are producing and the physical requirements to manufacture that specific PCB will ensure that you get a delivery date that you can plan on. A few common definitions:

Prototypes PCB

There are many different varieties of PCB Prototypes. Every project starts with quickly getting a PCB so that you test out your concept. Many times, the PCB designer isn’t even finished with the design when they submit Gerber data for production and have to use jumpers on the board when they get it – fast and cheap work.

However, if you are producing prototypes for testing on form, fit, and function and need to understand how all of the electronics will work with each other that is a different level of quality that is needed in your PCB. This is when you need to work with your PCB fabricator so that we can perform our rigorous design rule checks to ensure that your prototypes will be of the same quality as your production.

Pre-Production or Beta Run PCBs

In this case, this is when a customer is going to test out their production process or send units into the field or need many units for reliability testing. This is usually anywhere from 100 to several thousand pieces so the PCB fabricator needs to have the capacity to run all these production panels. Too often what happens when a customer’s goes from prototype to pre-production is that they run into issues as many things tend to change when you work with different companies. Laminate, multilayer stack ups, drill sizes, and many others can cause issues for customers.

In Benchuang Electronics’s case, we seamlessly move from prototype into pre-production as all of our factories use the same materials and the same Gerber data that we developed for the first run so that you will see no change in the product. Delivery times can be anywhere from 2 days up to our standard delivery of 15 days.

Production Quick Turn PCB

We usually see customers need higher volume quick-turns for emergency orders from customers or when a supplier can’t deliver. At Benchuang Electronics, we have the facilities that have the capacity and the experience of producing high-volume PCBs in very short lead times, and because we have already CAM’d the Gerber data, you will see no delay in production getting started.

What is a prototype PCB?

Printed circuit board prototypes are used across all areas of the consumer and industrial electronics industries. A PCB prototyping stage helps confirm that a circuit design will work as intended once the components are soldered in place on a real board. In short, a circuit board prototype provides a robust pre-production proof of concept.

A prototype PCB is often a simpler, more basic version of a finished production board, typically offering fewer advanced features and design flourishes. However, it needs to be an accurate, high quality and fully functional test version of the finalised circuit. At this stage, prototype PCB assembly should mirror the basic design, function and component load-out of the finished production run as closely as possible.

Mistakes or oversights at this stage can prove costly if not corrected before moving on to the full batch PCB manufacturing stage, so it’s extremely important to get your PCB prototyping done right. Fast turnaround circuit board prototypes are also of huge value to our clients: the earlier in the process we can observe and correct any potential issues, the more time and money you’ll save on delivery of the finished product.

What’s involved in delivering a PCB prototype?

Developing prototype circuit boards and component layout is a way of checking for bugs and issues on a ‘live’ working model of your design. It’s often used as a follow-up stage to a solderless breadboard version, although a skilled engineer will be perfectly capable of producing an accurate circuit board prototype from the raw data files. Breadboard circuit tests use clip-in components to test the basic layout and behaviour of a circuit under current. Whether or not you’re using breadboards as part of the overall design process, they’re not seen as a sufficiently robust test on their own. In order to move forward to the full PCB manufacturing stage with confidence, you’ll first need to produce a properly assembled and soldered prototype. Prototyping should always be overseen by an experienced technician who knows exactly what they’re doing. It’s a vital step in the delivery of a full production run for a completed bespoke PCB project, but it’s often a step that needs to be completed to a tight deadline.

Why might clients need a fast PCB prototyping service?

There are a number of reasons a client may want a printed circuit board prototype delivered quickly after finalising their circuit design. These can include:

- Peace of mind at every phase of a project, and especially prior to moving forward with a finalised design to the full batch production stage

- Reduced development timelines, helping lower overall project cost while also speeding up your time to market

- Pressing deadlines – these can come either from customers for faster product supply, or to meet tight booking and shipping timescales for upcoming industry showcases

Prototype PCB Assembly

Prototype PCB Assembly In 4 Steps

- Set up your printed circuit board

- Import your BOM

- Get your quote fast

- Complete your order

Having PCB prototypes made is a part of the best practices approach to product design. Using prototypes plays an essential and cost-effective way to capture and identify design issues before potentially large investment and expense of production.

Our No minimum quantity prototype services include:

- FREE DFM service (Design for Manufacturing)

- Your choice of solder mask color

- HDI, flexible, rigid-flex PCBs

- Component sourcing

- Turnkey PCB assembly

Getting your product to market is essential if you want to stay ahead of your competition and generate much-needed revenues. But before selling your products, you need to get a sense of confidence in your PCB assembly – a proof of concept to evaluate your PCB design before proceeding with production.

Considering the time constraints that exist, the PCB prototype phase has to be completed quickly because a lot depends on it. And, often more than one prototype build needs to be done before all design issues have been resolved. This could get very expensive and consume valuable time.

Fast Turn PCB Manufacturer

Quickly getting your electronic product to market isn’t just a question of getting a PCB that is “good enough” quickly, it’s also about producing that product at scale throughout the rest of the process.

That's where printed circuit board fabrication experience and true manufacturing capabilities become critically important. It's not enough for a PCB manufacturer to just deliver low-quality and low-cost prototype circuit boards. To reach the market quickly you need, a PCB manufacturing partner who is able to produce at all of the different development stages with consistency and at a competitive cost while still meeting short turnaround timelines.

The fact of the matter is that many PCB manufacturers may be capable of producing high-quality PCBs at a small-scale or in large volumes, but no one can do both. From prototype to beta builds, pre-production and into full production, you need a circuit board partner that will be with you all the way to ensure that your product sees no variation in its construction.

Get started with PCB prototype

- Prototype pcb assembly

- Quick turn pcb, pcb prototype service

- Blind vias, buried vias, Ultra HDI PCB

- High frequency low loss PCB material

- Low loss high speed PCB materials