What Kind of Circuit Boards Are Found in Motorcycles? Comprehensive Technical Breakdown

Types of PCBs in Motorcycles: Core Variants for Critical Systems

Modern motorcycles rely on specialized printed circuit boards (PCBs) to power everything from engine control to rider safety features. These PCBs are engineered to withstand harsh automotive environments—extreme temperatures, vibration, moisture, and mechanical stress—while delivering reliable performance. Below are the key types of circuit boards found in motorcycles, each tailored to specific functional needs.

Rigid PCB: The Workhorse of Motorcycle Electronics

Rigid PCBs are the most common circuit boards in motorcycles, built on inflexible substrates like FR-4 (fiberglass-epoxy composite) that offer structural stability and durability. Compliant with IPC-2221 standards, they excel in fixed-position applications where mechanical flexibility is unnecessary but reliability under stress is critical.

- Technical Specifications: Thickness ranges from 1.6mm to 3.2mm; copper weight 1oz–2oz (35μm–70μm); operating temperature -40°C to 125°C.

- Key Advantages: Cost-effective for high-volume production; compatible with standard electronics manufacturing processes; supports complex component integration.

- Motorcycle Applications: Engine Control Units (ECUs), instrument clusters, battery management systems (BMS) for electric motorcycles, and lighting control modules. For example, the ECU of a touring motorcycle uses a 4-layer rigid PCB to host microcontrollers, sensors, and power management ICs, ensuring precise fuel injection and ignition timing.

Flexible Printed Circuit: Conformal Integration for Tight Spaces

Flexible printed circuit (flexible PCB) is a pliable circuit board built on polyimide (PI) substrates, designed to bend, fold, or conform to irregular shapes—solving the challenge of integrating electronics into motorcycles’ compact, curved spaces. Adhering to IPC-2223 standards, it eliminates bulky wiring harnesses and reduces assembly complexity.

- Technical Specifications: Thickness 0.1mm–0.3mm; copper weight 0.5oz–1oz (17μm–35μm); 100,000+ cyclic bend resistance (radius 3x board thickness).

- Key Advantages: 40% lighter than rigid PCBs; reduces device volume by 30%; resistant to vibration-induced damage.

- Motorcycle Applications: Dashboard displays (conforming to curved instrument panels), handlebar control modules (adapting to tight wiring channels), and seat heating systems (fitting under upholstery). High-end sport bikes use flexible printed circuit to connect LED indicators to the handlebar controls, minimizing wiring clutter and improving aerodynamics.

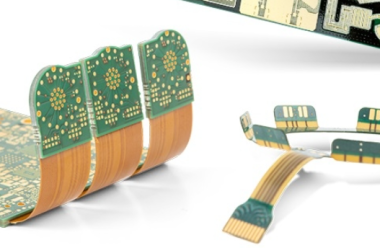

Rigid-Flex PCB: Balancing Flexibility and Stability

Rigid-Flex PCB combines rigid and flexible sections into a single integrated circuit board, leveraging the structural stability of rigid substrates and the conformal flexibility of polyimide. Compliant with IPC-2222 standards, it is ideal for motorcycle systems requiring both component mounting (rigid sections) and dynamic connectivity (flexible sections).

- Technical Specifications: Rigid layers (FR-4, 1.6mm) bonded to flexible layers (PI, 0.15mm); layer count 4–8; operating temperature -40°C to 150°C.

- Key Advantages: Eliminates connector failure points; reduces assembly time by 25%; withstands vibration (20g, 10–2000Hz) better than separate rigid+flex assemblies.

- Motorcycle Applications: Electric motorcycle throttle bodies (flexible sections adapting to movement, rigid sections hosting sensors), ABS control modules (integrating with wheel hubs), and convertible motorcycle roof systems (connecting moving panels to the main ECU). Adventure motorcycles often use Rigid-Flex PCB in their traction control systems, as it balances durability with space efficiency.

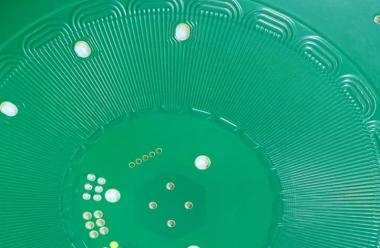

Aluminum PCB: Thermal Management for High-Heat Applications

Aluminum PCB (metal-core PCB) features a base layer of aluminum that acts as a heat sink, making it critical for motorcycle systems generating significant thermal energy. Compliant with IPC-2221/2226 standards, it dissipates heat 5x faster than traditional FR-4 rigid PCBs, preventing component overheating.

- Technical Specifications: Aluminum base thickness 1.0mm–3.0mm; dielectric layer (thermal conductivity 1–5 W/m·K); operating temperature -55°C to 175°C.

- Key Advantages: Thermal resistance as low as 0.8°C/W; improves component lifespan by 30%; resistant to thermal shock.

- Motorcycle Applications: LED circuit board systems (headlights, tail lights, turn signals), engine-mounted sensors (exposed to exhaust heat), and electric motorcycle motor controllers. A touring motorcycle’s LED headlight uses an aluminum PCB to cool high-power LEDs (10W+), maintaining brightness and preventing premature failure in extended use.

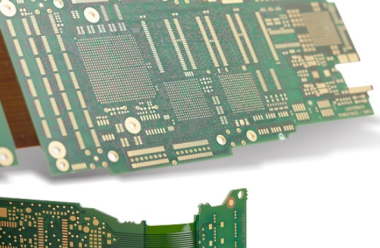

High Density Interconnect (HDI) PCB: Miniaturization for Advanced Systems

High density interconnect (HDI) PCB is a precision-engineered circuit board with fine traces (≤100μm width/spacing), microvias (≤100μm diameter), and via-in-pad technology—enabling miniaturization of complex electronics without sacrificing performance. Compliant with IPC-2226 standards, it supports high component density for space-constrained motorcycle systems.

- Technical Specifications: Trace width/spacing 50μm/50μm; layer count 6–12; component density up to 200 components/cm².

- Key Advantages: 50% smaller than standard rigid PCBs; supports high-speed signal transmission (up to 5Gbps); reduces power consumption by 15%.

- Motorcycle Applications: Advanced rider assistance systems (ARAS), GPS navigation modules, and Bluetooth connectivity units. Premium electric motorcycles use HDI PCB in their touchscreen dashboards, integrating GPS, media controls, and vehicle diagnostics into a compact, lightweight module.

RF PCB: Reliable Wireless Communication

RF PCB (radio frequency PCB) is designed for high-frequency signal transmission (≥1GHz) with low dielectric loss, ensuring reliable wireless communication in motorcycle systems. Built with materials like Rogers 4350B or Teflon (PTFE), it adheres to IPC-2225 standards and minimizes signal interference.

- Technical Specifications: Dielectric constant (εr) 3.0–3.8; controlled impedance (50Ω/75Ω); operating temperature -40°C to 150°C.

- Key Advantages: Low signal attenuation (<0.1dB/cm at 2GHz); resistant to electromagnetic interference (EMI); supports long-range communication.

- Motorcycle Applications: Tire pressure monitoring systems (TPMS), keyless entry modules, and 5G connectivity for electric motorcycle over-the-air (OTA) updates. Modern sport bikes use RF PCB in their TPMS sensors, transmitting pressure data to the instrument cluster with 99% accuracy at speeds up to 150mph.

Key Electronic Systems Using PCBs in Motorcycles

Motorcycle electronics are organized into specialized systems, each relying on tailored circuit boards to deliver functionality. Below are the critical systems and their PCB requirements, highlighting how each board type solves specific integration challenges.

Engine Control Unit (ECU)

The ECU is the “brain” of the motorcycle, managing fuel injection, ignition timing, and emissions control. It requires PCBs that support high-speed processing and sensor integration while withstanding engine heat.

- PCB Type: 4–8 layer rigid PCB or HDI PCB; aluminum PCB for high-heat ECUs in performance motorcycles.

- Technical Requirements: IPC-6012 Class 2 compliance; operating temperature -40°C to 125°C; resistance to oil and vibration.

- Quantifiable Impact: A well-engineered ECU PCB improves fuel efficiency by 10–15% and reduces emissions by 20% compared to outdated wiring systems.

Rider Safety Systems

Safety systems like ABS (Anti-lock Braking System), traction control, and airbag modules depend on PCBs that deliver real-time responsiveness and durability in high-stress scenarios.

- PCB Type: Rigid-Flex PCB (for dynamic connectivity) and RF PCB (for sensor data transmission).

- Technical Requirements: IPC-6012 Class 3 compliance (critical reliability); 1ms signal latency; vibration resistance (30g, 10–5000Hz).

- Quantifiable Impact: ABS PCBs reduce braking distance by 15% on wet roads, while traction control PCBs decrease wheel slip by 40% in off-road conditions.

Lighting Systems

Motorcycle lighting—headlights, tail lights, turn signals, and auxiliary LEDs—relies on PCBs that manage power distribution and thermal dissipation.

- PCB Type: Aluminum PCB (for high-power LEDs) and flexible printed circuit (for conformal lighting strips).

- Technical Requirements: IPC-2221 compliance; thermal conductivity ≥2 W/m·K; water resistance (IPX4+).

- Quantifiable Impact: Aluminum PCB-based LED headlights last 5x longer than incandescent bulbs, while flexible printed circuit lighting strips reduce wiring weight by 50%.

Infotainment & Connectivity

Modern motorcycles feature infotainment systems (touchscreens, audio) and connectivity modules (Bluetooth, GPS, 5G) that require compact, high-performance PCBs.

- PCB Type: HDI PCB (for miniaturization) and RF PCB (for wireless communication).

- Technical Requirements: Controlled impedance (75Ω for video, 50Ω for RF); component density ≥150 components/cm²; operating temperature -20°C to 85°C.

- Quantifiable Impact: HDI PCB-enabled infotainment systems reduce dashboard volume by 30%, while RF PCB ensures 99% connectivity reliability in urban and rural environments.

Electric Motorcycle Systems

Electric motorcycles (e-bikes) rely on specialized PCBs for battery management, motor control, and charging—requiring high current capacity and thermal resilience.

- PCB Type: Aluminum PCB (motor control), rigid PCB (BMS), and high density interconnect (charging modules).

- Technical Requirements: Current capacity up to 50A; thermal resistance ≤1°C/W; IPC-6012 Class 3 compliance.

- Quantifiable Impact: BMS PCBs extend battery lifespan by 25%, while motor control PCBs improve energy efficiency by 12% compared to conventional designs.

Common Components on Motorcycle PCBs

Motorcycle PCBs host a range of specialized components tailored to automotive-grade performance, each integrated to support the board’s functional role. Below are the most common components and their contributions:

- Microcontrollers (MCUs): The core processing unit (e.g., ARM Cortex-M series) that executes software for ECU, infotainment, and safety systems. MCUs on motorcycle PCBs typically operate at 32-bit, 80MHz–1GHz clock speeds, with built-in analog-to-digital converters (ADCs) for sensor data processing.

- Power Management ICs (PMICs): Regulate voltage (12V–48V) for stable operation of sensitive components, with overcurrent and overvoltage protection. Critical for electric motorcycle PCBs, where voltage fluctuations from the battery are common.

- Sensors: Include temperature sensors (NTC thermistors), pressure sensors (for TPMS), and motion sensors (accelerometers for traction control). These components interface with PCBs via low-noise traces, ensuring accurate data transmission.

- LED Drivers: Control current flow to LED circuit board systems, dimming lights and preventing overheating. Aluminum PCB-mounted LED drivers handle up to 2A per LED, with thermal shutdown protection.

- Connectors: Automotive-grade connectors (e.g., AMP Superseal) that secure PCB-to-wiring and PCB-to-component connections, with IP67 water and dust resistance.

- Capacitors & Resistors: Ceramic capacitors (for noise filtering) and thick-film resistors (for current limiting) that withstand vibration and temperature extremes. Motorcycle PCBs use high-temperature capacitors (125°C rated) to avoid failure in engine bays.

PCB Prototype & Electronics Manufacturing for Motorcycles

The development and production of motorcycle PCBs follow rigorous electronics manufacturing processes, with pcb prototype validation critical to ensuring performance in real-world conditions. Below is an overview of the manufacturing workflow and quality control measures:

PCB Prototype Development

- Design Phase: Uses ECAD software (e.g., Altium) to optimize trace routing, thermal management, and component placement—accounting for motorcycle-specific constraints (vibration, heat).

- Prototyping Process: Rapid pcb prototype production (3–5 days) via laser etching and 3D printing for small-batch testing. Prototypes are validated for fit (conformity to motorcycle components) and function (signal integrity, thermal performance).

- Testing: Includes vibration testing (per ISO 16750-3), thermal shock testing (-40°C to 125°C, 100 cycles), and electrical testing (continuity, insulation resistance). A pcb prototype for an ECU must pass 10,000 vibration cycles without trace damage.

Electronics Manufacturing for Mass Production

- Material Selection: FR-4, polyimide, or aluminum substrates; automotive-grade copper (oxygen-free for high conductivity); and lead-free solder (per RoHS standards).

- Assembly Processes: Surface Mount Technology (SMT) for component placement (accuracy ±0.1mm); through-hole technology for high-power components; and conformal coating (silicone or urethane) for moisture and chemical resistance.

- Quality Control: Automated Optical Inspection (AOI) for solder defects; X-ray inspection for hidden joints (e.g., in HDI PCB); and functional testing (e.g., ECU calibration, LED brightness validation). Manufacturers adhere to IATF 16949, the global standard for automotive electronics manufacturing.

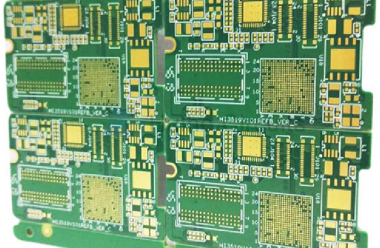

Multilayer PCB in Motorcycles: Advantages for Complex Systems

Multilayer pcb (3+ layers) is increasingly used in modern motorcycles for complex systems like ECUs, infotainment, and electric motorcycle BMS. Its layered structure—alternating conductive copper and insulating dielectric layers—enables high component density and improved performance.

- Technical Specifications: Layer count 4–12; trace width/spacing 50μm/50μm; via types (through-hole, blind, buried); compliant with IPC-6012 Class 2/3.

- Key Advantages:

- Reduced electromagnetic interference (EMI): Separate power and ground layers minimize noise, critical for RF PCB and sensor-based systems.

- Space efficiency: 2x more component density than single-layer PCBs, enabling miniaturization of infotainment and BMS modules.

- Thermal management: Inner layers can act as heat spreaders, reducing hotspots on high-power PCBs like aluminum PCB motor controllers.

- Motorcycle Applications: High-performance motorcycle ECUs (8-layer multilayer pcb), electric motorcycle BMS (6-layer), and advanced ARAS (10-layer HDI multilayer pcb). For example, a sport bike’s traction control system uses a 6-layer multilayer pcb to integrate MCUs, sensors, and power components in a compact footprint.

FAQs About Motorcycle Circuit Boards

What Is the Difference Between PCB and PCA in Motorcycles?

A PCB (Printed Circuit Board) is a blank board with conductive traces, while a PCA (Printed Circuit Assembly) is a PCB with components (MCUs, sensors, LEDs) installed. Motorcycle systems use PCAs for functional operation—e.g., an ECU PCA includes the PCB plus microcontrollers and power ICs.

How Are Motorcycle PCBs Tested for Durability?

Motorcycle PCBs undergo rigorous testing per automotive standards: vibration testing (ISO 16750-3), thermal shock testing (-40°C to 125°C), moisture resistance testing (IPX4+), and chemical resistance testing (exposure to oil, fuel, and cleaning agents). IPC-6013 Class 3 compliance requires 100% functional reliability after 1000 hours of environmental stress.

Why Is Aluminum PCB Preferred for Motorcycle LED Systems?

Aluminum PCB’s metal core dissipates heat 5x faster than FR-4, preventing LED overheating (a common cause of premature failure). LED circuit board systems on motorcycles generate significant heat (10W+ per bulb), and aluminum PCB’s thermal conductivity (1–5 W/m·K) ensures consistent brightness and extends LED lifespan by 5x.

Can Flexible Printed Circuit Withstand Motorcycle Vibration?

Yes—flexible printed circuit adheres to IPC-2223 standards, with 100,000+ cyclic bend resistance and vibration tolerance (20g, 10–2000Hz). Its pliable polyimide substrate absorbs vibration better than rigid PCBs, making it ideal for handlebar controls and seat systems where movement and vibration are constant.

What Role Does High Density Interconnect Play in Electric Motorcycles?

High density interconnect enables miniaturization of critical systems (BMS, charging modules) in electric motorcycles, where space and weight are at a premium. HDI PCB’s fine traces (≤100μm) and microvias reduce module volume by 30%, while supporting high component density (≥150 components/cm²) for complex power management.

Conclusion

Motorcycles rely on a diverse range of circuit boards—rigid PCB, flexible printed circuit, Rigid-Flex PCB, aluminum PCB, high density interconnect, and RF PCB—to power their advanced electronic systems.

![Understanding PCB Costs & Pricing [Your Complete Guide] Understanding PCB Costs & Pricing [Your Complete Guide]](https://hdicircuitboard.com/wp-content/uploads/elementor/thumbs/Understanding-PCB-Costs-Pricing-Your-Complete-Guide-qzzhe6mcaxuolkux3xalfktgavumi9y1aqfbs9bpv4.webp)